Rotary drums, used in applications ranging from drying and granulation to thermal processing, are subject to significant mechanical stresses over time. One of the most critical components of a rotary drum maintenance program involves maintaining proper drum alignment and structural integrity of the tire, or riding ring, via the interface with the mounting assembly. Over time, wear, thermal cycling, and dynamic loading can cause issues, requiring regular inspection and maintenance of the tire-to-shell interface.

FEECO utilizes the floating tire mounting style, which allows the drum to operate within the predetermined ovality, while also allowing for thermal expansion and streamlining maintenance. In maintaining a floating tire and its mounting components, a key progression of steps is required: tire shimming, remounting, and replacement—each addressing different stages of wear and misalignment.

Tire Shimming (and Reshimming)

The first line of defense in protecting tire and alignment integrity is tire shimming, or more often, reshimming.

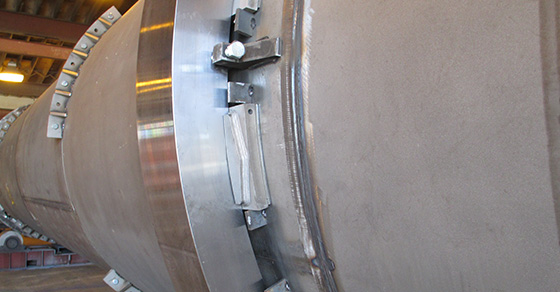

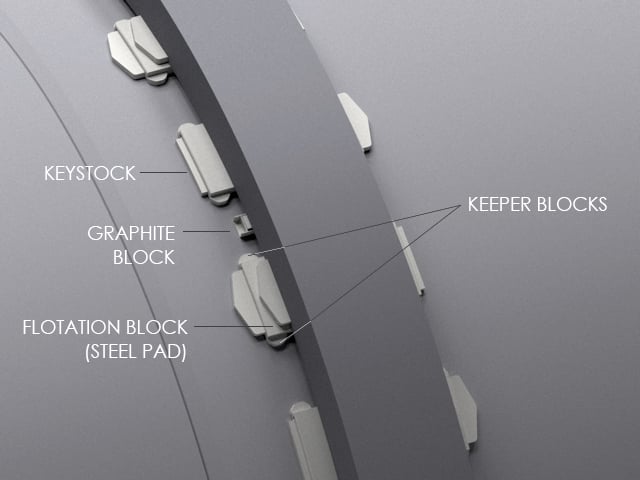

The floating tire mounting assembly consists of steel pads (flotation blocks) on the drum, held in place with what are known as keeper blocks. A block of graphite also mounted on the drum provides lubrication as the tire, held in alignment by side keeper blocks, passes over the flotation blocks. In this way the tire is “floating” in place, as it is not fixed to the drum.

Over time as flotation blocks, which are made of a softer metal to promote wear on blocks instead of the tire, become worn, creating a gap in the interface between block and tire bore. This gap allows the tire to freely move around the drum, a process known as tire creep, which, if allowed to persist, can begin wearing away keeper blocks, eventually allowing the tire to move axially on the drum.

To prevent this, shims are placed under flotation blocks to restore the proper tire-block interface.

In most cases, FEECO recommends reshimming every three to seven years. However, operators and maintenance personnel should regularly inspect the mounting system and tire for signs of wear, as well as tire creep. FEECO recommends an annual inspection be carried out by the OEM or other qualified service provider as well, to catch problems before they can escalate.

When done early and correctly, shimming can extend the life of the tire and avoid more intensive repairs.

Tire Remounting

Once the flotation blocks become worn to the point that reshimming is no longer effective, a tire remount must be performed. If axial tire movement is allowed to persist due to excessive tire creep, both tire and drum shell risk significant damage.

Unlike with reshimming, where shims are simply added to the assembly, a remount involves removing and replacing all mounting assembly components – keeper blocks, side keepers, and flotation blocks. Depending on historical maintenance and operating conditions, remounting is typically required every two reshims, often 10-15 years after initial installation.

During the remounting procedure, the drum shell may also be inspected for signs of wear, shell cracks due to fatigue, or other damage. Upon inspecting the shell, replacing the new mounting components, and remounting the tire, it is recommended to check wheel-to-tire alignment. FEECO recommends a laser alignment to ensure the wheels are aligned properly with tires. If tires have uneven wear, grinding and alignment is also recommended.

Rotary drum with tire removed and shell repair in progress

Tire Replacement

While tires are engineered to provide many years of service, they are still a wear component that eventually require replacement.

Minimal wear, such as timing marks, can be addressed through tire resurfacing, but when tires experience fatigue cracks, deep scoring, excessive wear, or out-of-round conditions, replacement is necessary. The frequency of replacement depends largely on operating conditions and how well the system has been maintained, but on average is around 20 years.

When tires start to experience these signs of wear, maintenance managers should begin planning for replacement, as the replacement tire will have a longer lead time than shim and remount kits. While split tires can offer a quicker installation by avoiding the prework to provide access to the end of the drum, FEECO recommends using only single-piece tires, as these offer the most structural integrity.

As a major structural component of the drum, replacing the tire is comparably more involved and costly than reshimming or remounting. The old tire will need to be removed, the drum shell cleaned and inspected, and the new tire and mounting system set and aligned.

New tire installed on repaired drum shell

Choosing the Best Approach

For plant managers unsure of the state of their tires, understanding which maintenance procedure is appropriate depends on a variety of factors including the degree of wear, operational symptoms, and the drum’s service history. Regular inspections, including tire creep measurement, are essential to identifying issues early and selecting the right intervention.

By addressing tire issues proactively—whether through shimming, remounting, or replacement—producers can reduce unplanned downtime, extend the life of the drum, and maintain optimal processing conditions.

For these reasons, having a reliable service partner that can act as an extension of your maintenance team is essential.

Conclusion

The tire-to-shell interface plays a vital role in rotary drum performance and service life. As such, keeping it in proper condition is a key part of any maintenance program. Whether through minor adjustments or full-scale replacement, understanding the role of shimming, remounting, and tire replacement allows operators to take a proactive, cost-effective approach to rotary drum maintenance.

Providing custom equipment and service support since 1951, FEECO’s customer service team can inspect your rotary drum and assess the best approach to remediating any issues you may be experiencing. For more information on tire shimming, remounting, or replacement services, contact us today!