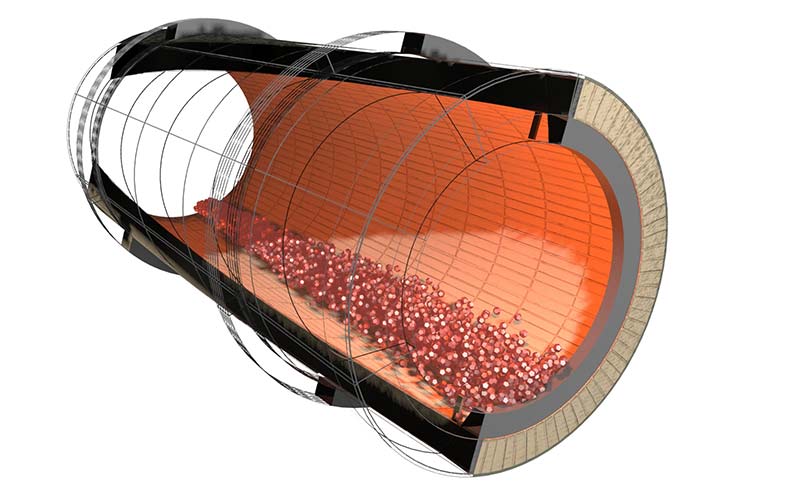

In the field of continuous bulk solids processing equipment, retention time can be one of the most influential variables in a process setting, particularly when processing material in a rotary dryer, rotary kiln, granulator, or other type of rotary drum.

Despite its importance, however, retention time is often a misunderstood concept. Here’s a look at exactly what retention time is, why it’s important, and how it works in a rotary drum.

Understanding Rotary Drum Retention Time and Why It’s Important

Also often referred to as residence time, retention time is the amount of time for which a material is processed in a given piece of equipment. In most process settings, producers must be able to reach a specific retention time in order to carry out their intended objective, which may be (among other things) to:

- Reach a specific moisture content

- Initiate or complete a chemical reaction or phase change

- Allow a coating to absorb onto a substrate

- Form granules within the desired particle size distribution (PSD)

- Achieve a uniform coating on granules

The ability to achieve these objectives is the foundation of many mineral and chemical processing operations, making proper retention time essential. This is particularly true of drying, granulation, and high-temperature thermal processing applications where retention time can mean the difference between on-spec product and material loss.

The importance of retention time may vary across operations, but is always important in the initial drum sizing process, for both quality and efficiency purposes.

In the case of quality, for example, a rotary dryer sized without a proper understanding of retention time could result in the material reaching the target moisture content half way through its travel in the drum, meaning the material would continue to be dried for the remaining half of the unit. This could cause the material to become overdried and break down into fines. Similarly, if the drum was not long enough to accommodate the necessary retention time, material could exit the drum before it has reached the required moisture content.

In other cases, quality might not be affected, but the drum may be oversized, resulting in lower efficiency, and ultimately a larger capital cost than necessary.

As such, producers must first identify the retention time at which their material will reach the desired objective. This is done through testing.

Identifying Rotary Drum Retention Time Through Testing

Whether the process centers around drying, granulation, coating, or high-temperature thermal processing, identifying the retention time at which the desired reaction occurs (among other parameters) is a common objective of testing in the FEECO Innovation Center.

The facility boasts a wide array of batch- and pilot-scale equipment for testing various processes. Depending on the process, testing typically begins at batch scale in small equipment, allowing smaller samples of material to be taken and analyzed at regular intervals to identify an approximate retention time.

Once a rough retention time is established, it can be used as a guide to further refine retention time during continuous pilot-scale testing.

Measuring Retention Time in a Continuous Rotary Drum

While retention time seems simple in theory, the complexity comes in when working with a continuous process. In a continuous production run, there are no batches, and no real delineation between “start” and “finish;” material is constantly going in and coming out of the drum simultaneously, making it difficult to determine the true length of time for which a given portion of material has been processed.

In cases where a batch unit is not available for testing, or when looking to identify the optimal retention time in a continuous test setting, two different tactics can be used to measure retention time: the inclusion of a tracer, or the measurement of drum volume. In a commercial setting, the intended retention time should already be known, so measurement is only used as a way to confirm the process is operating as designed.

Introducing a Tracer

A tracer such as a dye or chemical is not always permissible due to product composition or contamination concerns. Where allowable, however, a tracer can be an extremely useful tool in determining retention time; by measuring where the tracer begins to exit the drum, and where the tracer is no longer seen, one can identify the average retention time.

Measuring Drum Volume

Retention time can also be defined by measuring material bed volume (volume of material in the drum) or material bed weight (weight of material in the drum) when the process is at steady state. At steady state, the material is being fed into and discharged from the drum at the same rate. By dividing material bed volume or material bed weight by the volumetric flow rate or mass flow rate, the average retention time can be determined (respectively).

It’s important to understand that retention time is always an average in a continuous setting. Material typically does not exit the drum at the exact same time, even though it was fed into the drum at the same time – some material will exit a little earlier, and some a little later, with the majority falling somewhere in between.

Process Variables That Influence Rotary Drum Retention Time

Once the target retention time is known, several process parameters can be manipulated or investigated during testing in order to reach the target time. Among the most influential are drum speed, drum slope, and the use of dams.

Drum Speed

Drum speed is measured in rotations/revolutions per minute, or RPMs. In general, the faster the speed, the more quickly material will move through the drum. However, this is also heavily dependent on the material characteristics. If the material is made up of fines or is highly flowable, material may just “slip” along the drum shell if it’s moving too quickly.

In other cases, a less flowable or more sticky material may require higher speeds to keep the material moving.

Drum Slope

Drum slope, or the angle at which the drum is set, is adjusted to use gravity to encourage more or less movement through the drum. As with drum speed, material characteristics must be taken into account in identifying the optimal slope; some materials may require a steeper angle than others to encourage material movement through the drum.

Incorporating a Dam

Dams are also a helpful tool in modifying retention time. A drum dam works on the same principle as a river dam; material builds up behind the plate, causing it to stay in the drum longer. Eventually, material flows over the dam and on to discharge. Both dam placement and height can be adjusted to change retention time.

Particle Size Distribution

It’s important to understand that while it’s not necessarily a variable that can be manipulated, particle size distribution also has a large influence on retention time; in general, larger particles travel faster through the drum than smaller particles. As such, a feedstock with a wide range in particle size distribution will have a wider window of retention time, because there will be a greater difference in the amount of time it takes for larger particles to exit the unit than for smaller particles.

At the same time, particles with a more uniform particle size distribution will have a tighter window of retention time, because there is little difference in the speed at which particles will move through the drum.

Adjusting Retention Time in a Commercial Rotary Drum Operation

Achieving the right retention time is fairly simple in a test setting, where the parameters can be flexibly adjusted to reach the target. In a commercial setting, however, producers are working with a fixed unit and must use other tools to modify retention time in the event that process or material conditions move away from the initial plant design.

The most common way of increasing rotary drum retention time in a commercial-scale plant is to incorporate a dam. The most common way to slightly decrease retention time in a commercial rotary drum is to increase the speed.

Conclusion

Retention time is an essential aspect of reaching product quality goals and doing so efficiently. Understanding its importance and how to properly measure it are crucial to the success of any rotary drum project. As such, optimal retention time should be established as part of a thorough testing program, where variables can be modified and adjusted to achieve the desired results.

FEECO engineers the world’s most reputable rotary drums for applications ranging from drying and cooling, to granulating, coating, and even high-temperature processing. Our Innovation Center provides the ideal testing capabilities for determining retention time and other data necessary for the design of a commercial-scale rotary drum. For more information on our rotary drums or testing capabilities, contact us today!