A pugmill mixer, or paddle mixer, is a horizontal, continuous industrial mixer used in a variety of applications for processing bulk solids to achieve a range of objectives.

These rugged mixing units are highly flexible and have become an essential tool in many processes. They can be used as a stand-alone agglomeration, mixing, or conditioning device, or they can be integrated into a larger agglomeration process, where they serve to prepare the material for downstream processing in some way.

Most notably, they are often one of the key pieces of equipment in processing:

- Manure

- Copper concentrates

- Steel mill by-products

- Fly ash

- Animal Feed (MCP, DCP)

- Fertilizers

The broad spectrum of applications in which pugmill mixers can be employed is an example of the machine’s flexibility, but pugmill mixer design must be configured around the unique specifications of the material to be processed in order to reach an effective mixing solution. Here is a look at how this critical device is engineered to produce an optimal processing solution.

Questions to Ask Prior to Pugmill Mixer Design

Before beginning the sizing and design process, there are a few questions that should be addressed to confirm that the pugmill is the ideal mixer for the application:

Is the Pugmill Mixer’s Action Appropriate for the Application?

Pugmill mixers utilize a high-torque kneading and folding motion that provides an intimate mixture of feedstock materials, whether the materials consist of all solids, or a combination of solids and liquids. While this action offers an effective solution for many materials, it is not ideal for all materials.

Materials requiring a high level of densification may be better served in a pin mixer; the pugmill’s kneading motion produces less densification compared to the intense spinning action of the pin mixer. Additionally, when a liquid and solid tend to repel each other, a pugmill may not sufficiently force them to combine.

Will the Material’s Consistency Be a Problem?

While pugmills adeptly process slurry and sludge-like materials, materials that are especially sticky can pose a problem, particularly if the material exhibits cementitious properties. In a case such as this, there is potential for the material to build up and harden into a cement-like form within the mixing trough. Some sludges and manures may also tend to build up on paddles and shafts, which can be problematic as well.

Sticky materials such as these may do better in a different type of mixer, or may require dried material to be incorporated into the feedstock to reduce the stickiness of the material (a practice called back-mixing). Utilizing paddles with some overlap can also be helpful when working with sticky materials.

Will Testing Be Needed?

Depending on the material, the process goals, and what data has already been gathered, testing may or may not be necessary.

Testing may not be needed if the process is already well defined, or a reasonable amount of data can be used to theorize the project. If the process is new, however, or variation is characteristic of the source material, or simply not enough information is available, testing in a facility such as the FEECO Innovation Center is a good way to work out unknown variables and reduce the potential for surprises after scale-up.

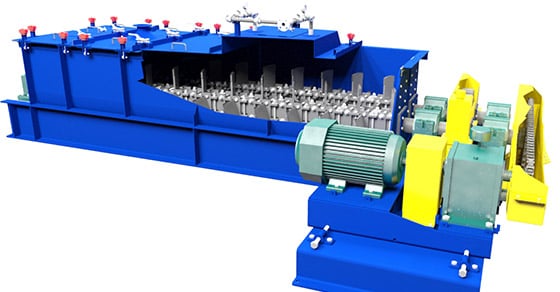

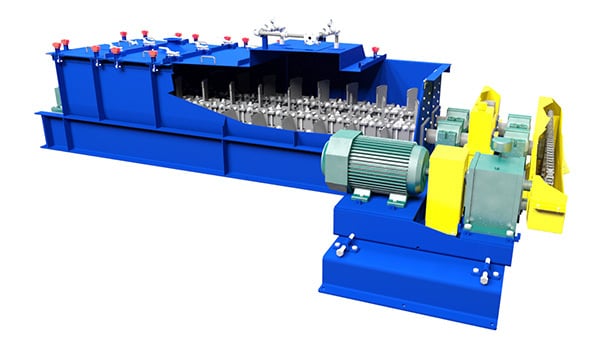

3D Model of a FEECO Pugmill Mixer/Paddle Mixer

Pugmill Mixer Design Considerations

As with most any process equipment, the sizing and design of a commercial-scale, continuous pugmill mixer is a complex process that must balance a variety of factors to yield the most optimal processing solution.

Pugmill sizing is largely focused around two key parameters: retention time and capacity.

Retention Time

Retention time (also referred to as residence time) is the amount of time the material will need to be in the mixer to achieve the desired results. Retention time is directly related to the size of the equipment, with longer retention times requiring a longer and/or wider mixer.

The amount of retention time required is generally a result of the machine’s objective; is it being used to simply mix dry components? Must it produce a homogeneous blend of liquid and solid feeds? Or will it be required to roughly agglomerate multiple feed components?

A 1-minute retention time is common, but not always appropriate, so the material will need to be examined to determine what is ideal for the given situation if not already known.

A slightly shorter residence time may be sufficient when simple conditioning is needed, or when the unit is just mixing dry ingredients. For applications that require a thorough mixing of both solid and liquid feeds, retention time may run significantly longer – 2-5 minutes. This is commonly seen when mixing steel mill by-products prior to a briquetter, as the briquetter requires an extremely uniform feedstock.

Capacity

Pugmill mixers can be designed to process material from 500 lb/hr all the way up to 250 TPH. In general, the higher the capacity, the wider the trough will be.

Theoretical calculations and machine limitations are used to help determine the balance between the length and width of the mixer.

Customizations

The base of a pugmill is fairly standard: a U-shaped trough is mounted on a structural steel base. Twin shafts fitted with adjustable paddles fully extend the length of the mixer and are sealed by trough end seals at each end. Shafts are flanged for easy removal and maintenance. A steel cover closes off the internals. Mechanical components include a motor, concentric shaft reducer with high-speed coupling, and drive assembly.

The dual shaft design creates a turbulent mixing bed and retains more flexibility when more than two feed components are present, as the paddles tend to “throw” the material into the air somewhat between the two shafts.

A number of modifications can be made to the pugmill to tailor its performance to the material being processed. Common customizations are summarized here:

Spray Systems

If the pugmill mixer will be used to incorporate a liquid feedstock or binder, a spray system will be needed. The spray system is mounted with piping and spray tips over each shaft. Sprays can also be located over the center of the machine so they spray the liquid onto the material as it is being tossed in the air.

The liquid component distribution is a result of how far above the material bed the spray system is positioned. A standard pugmill mixer is fitted with a flat cover over the spray system, so the spray system is located at about the same height as the top of the trough. When a greater distribution of the liquid component is needed, however, the spray system must be positioned higher above the bed. In general, the higher the spray system is positioned, the greater the distribution of the liquid component across the material bed. For this reason, mid- and high-height cover assemblies are available as an alternative to flat covers.

Drive Assembly

Various drive assemblies are available. The selection of which is most often based on buyer preference. The following drive assemblies are available:

- Direct drive

- Chain & Sprocket

- Belt and Sheave

In cases where the allotted footprint of the unit is limited, an in-line drive can also be used to save on space.

Paddles

The most customizable aspect of the pugmill mixer is the paddle assembly. Placement, direction, and paddle facings can all be tailored to suit the application at hand.

Placement of the paddles is flexible to allow for adjustments as needed; paddles can be added or removed to adjust the mixing pattern. Paddles are also reversible. This increases bed depth and retention time, creating a more thorough mixture if needed.

The paddles themselves can be faced with a variety of materials to better tolerate the material being processed. For example, ni-hard and ceramic facings are available for especially abrasive materials.

Misc. Customizations

There are a variety of miscellaneous customizations that may be necessary based on the specifications of the material.

Enhanced Clean-out & Observation

The potential for tramp material or large lumps of material should be considered during the design stage. In situations where the possibility of tramp material is high, doors at the bottom of the trough may be desirable to allow for easier and faster cleaning, or for removing material during a process upset.

Similarly, observation windows or access doors may be included in the mixer cover to allow for in-process viewing and/or easier cleanout.

FEECO pugmill mixer with access/inspection doors

Materials of Construction

Special materials of construction may be needed depending on the degree of corrosion protection necessary.

Mechanical Components

Several of the mechanical and control components on the pugmill are also customizable.

An optional variable frequency drive, or VFD, allows the motor to sense and respond to changes in the mixer. This is beneficial because it can be programmed to limit how much current/power is transmitted to the motor, helping to prevent the mixer shafts from breaking. For example, if a large piece of tramp metal were to enter the machine and become lodged between the paddles stalling the mixer, the VFD would likely sense this overload condition and shut off the mixer to prevent further damage.

Zero-speed switches can also be helpful in this type of situation to alarm the operator when the shafts stop rotating. Often both a VFD and zero-speed switches are recommended.

Thermocouples and/or infrared temperature sensors can be incorporated into the unit if heat is a concern, such as when working with an exothermic reaction.

Automation

Pugmill mixers can also be integrated into a process control system, so process data can be collected, monitored, and even trended through a user interface for the operator. This might include data points such as:

- Current (amps)

- Feed rate

- Horsepower

- Torque

- And more…

Testing in the Design Process

While pugmill mixers offer a high level of flexibility, this can also make the most optimal design unclear, requiring testing to be carried out.

Testing in a facility such as the FEECO Innovation Center can help to define process variables and indicate the customizations needed before scale-up, reducing surprises later.

Testing being carried out in a pugmill mixer in the FEECO Innovation Center

“One of the nice things about the Innovation Center, is that we can test material on a continuous basis as part of a larger process,” says Chris Kozicki, FEECO Agglomeration Process Sales Engineer. “A lot of our customers appreciate that we can incorporate drying, screening, and a recycle circuit if needed. It really helps them to get their concept worked out on a high level.”

Conclusion

Pugmill mixers are a highly diverse continuous mixer. An already-essential component in many processes, the applications in which they can be utilized continue to grow.

In sizing and designing a custom pugmill, a number of considerations should be taken into account in order to produce the most ideal processing solution possible. While this can be based solely on known data points, testing may be necessary to define process variables.

FEECO has been providing custom pugmill mixers since 1951. With experience around hundreds of materials, we can test, design, and manufacture a pugmill suited to your exact needs. For more information on our pugmill mixers, contact us today!