Controlling build-up in rotary drums is critical to maintaining process efficiency, upholding product integrity, and avoiding unnecessary upsets and downtime. Buildup can occur as a result of material sticking to itself, or to the interior of the drum, and can pose larger problems if not quickly addressed. One of the most common ways to control buildup is through the addition of a knocking system.

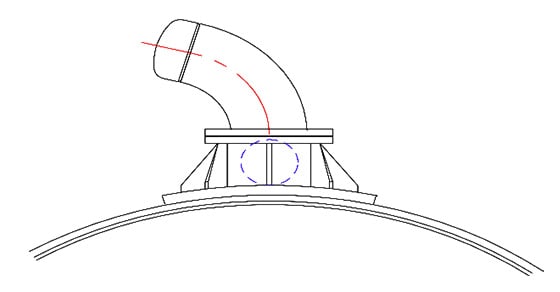

Knocking systems can be implemented to “knock” the buildup off of the drum as it rotates, helping to prevent material from building up on the inner walls of the shell. FEECO offers two primary approaches to knocking systems, as described in our newly updated knocking systems brochure.

Whether purchasing a new rotary drum, or retro-fitting a solution to an existing drum, both ball and tube knockers and pneumatic hammers offer an effective solution for reducing buildup.

The brochure takes a look at the features of each type of system, and goes over the many factors to consider when choosing a knocking system for a given application.

FEECO is a leader in providing custom rotary drums, including dryers, coolers, coating drums, and more. For more information on we can help you to reduce buildup in your rotary drum, contact us today!

Download the Brochure: Rotary Drum Knocking Systems (11436 downloads )