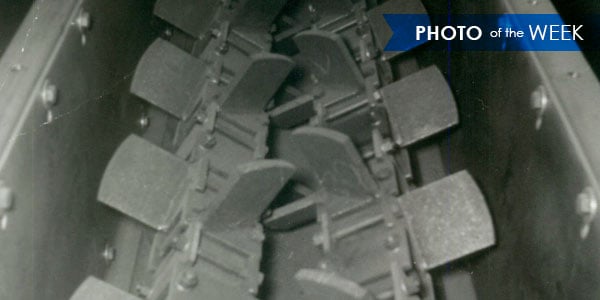

Our photo this week is a paddle mixer from 1964.

Paddle mixers agglomerate, condition and mix various materials- wet and dry- via two rotating shafts with outward-extending paddles. As the shafts rotate, the paddles move the material, creating a kneading and folding over effect. Though this process thoroughly mixes the material, a liquid spray system may be added to disperse a binder if needed.

Paddle mixers, also known as pugmill mixers, are ideal for bulk applications and heavy duty materials, and each can be custom configured to suit particular material needs. FEECO paddle mixers have agglomerated fertilizer, pesticides and flue dust; conditioned fly ash, cement dust and lead fume; and mixed sludge, woodchips and dyes in addition to countless other materials.

For more information on paddle mixers, contact us today!