Originally developed to process carbon black, the pin mixer is an industrial mixer that has evolved to meet a variety of needs across many industries, making it a critical processing tool in producing everything from chemicals to minerals.

The hugely successful and widespread use of the pin mixer can largely be attributed to its multi-functional operating capabilities: the mixer is capable of mixing, pelletizing, and densifying material – all in the same unit and in a matter of seconds. Unbeknownst to many, this functionality is made possible by a unique working principle.

About Pin Mixers

Pin mixers are a horizontal, continuous mixer composed of a single rotor shaft housed in a stationary cylindrical casing. The shaft is fitted with several pins that extend outward radially, leaving a small clearance between the pin ends and the shell’s interior diameter. Pins are arranged in a helical pattern that works to advance material through the mixer, or can be customized to accommodate varying process goals.

As material is fed into the mixer inlet, a spray system distributes the liquid binder over the agitated material bed at a predetermined liquid-to-powder ratio. The shaft (and pins) spin at several hundred RPMs, creating a turbulent processing environment and medium-shear spinning action.

The diverse functionality of the pin mixer allows it to be used as a stand-alone device for carrying out mixing and/or pelletizing, or as a preconditioning step in a larger agglomeration setup, particularly when a disc pelletizer is employed.

Pin Mixer interior shown without top half of shell

Pin Mixer Operating Zones

As a form of tumble growth agglomeration, processing in a pin mixer is governed by many of the same principles as other agitation agglomeration equipment:

- Motion and binder are used to form agglomerates.

- Liquid binder causes fines to become tacky, so they will pick up additional fines as they tumble, growing the pellets to a larger size in a layering effect known as coalescence.

- Material and binder composition have a significant influence on forming the desired pellet product.

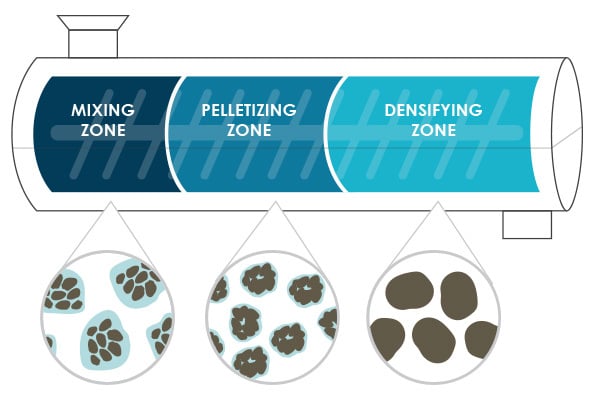

Outside of these conditions, the pin mixer relies on a unique operating theory that centers around three dedicated, but structurally undefined zones in the mixer’s interior in order to carry out mixing, pelletizing, and densification.

Zone 1: Mixing

The first 15-20% of the mixer accomplishes the mixing of feed components. In this zone, mechanical and aerodynamic forces cause the fine particles and droplets of liquid binder to collide with each other. The result is a homogeneous mixture of solid and liquid feed materials.

Once thoroughly mixed, the mixture will begin to agglomerate, or pelletize.

Zone 2: Pelletizing

As the blend moves through the length of the mixer, the now-tacky particles begin to join together, forming larger pellets made up of loose particles. As these agglomerates move through the mixer, centrifugal force continuously causes them to roll down and along the mixer’s interior, encouraging the joined-together particles to morph into spherical pellets.

As pellets form, they transition away from the inlet, so the addition of new material tapers off. Some densification of particles occurs in this zone as well.

Zone 3: Densifying

Without any new material being added, and with the larger pellets encouraging added centrifugal force, the pellet action shifts from formation to densification. This occurs in the third and remaining zone of the mixer. In this zone, the action occurring between the pellets, as well as that between the pellets and the interior shell and pins, causes the pellets to gain in density as water and air volume within each pellet is forced out. Pellets are also polished as they roll against the mixer’s interior shell.

The pellets being discharged from the mixer, often referred to as micro pellets in this setting, are uniform in makeup and physical characteristics, and ready for either additional processing or product finishing (drying, coating, etc.).

Depiction of the zones in a pin mixer

Pin Mixer Retention Time

Because retention or residence time is largely based on mixer length, the degree of agglomeration and densification is also a factor of retention time – the amount of time that the material is processed in the mixer.

While other factors do come into play, in general, the shorter the retention time, the less agglomeration that occurs; the longer the retention time, the more dense the granules will be, because they’ve had a longer time to move through the mixer, gaining in density.

In this way, the pin mixer can be used to accomplish different objectives by adjusting the retention time. For example, by using a lower retention time, pelletizing can occur without additional densification. Or, at an even lower retention time, the material may simply be mixed.

This capability is often used for dry blending, dust suppression, conditioning, and mixing, among other tasks.

Pin Mixer Process Development

The flexibility of the pin mixer makes it ideal in a wide variety of settings, but at the same time, this flexibility can be overwhelming when seeking a specific objective. For this reason, and because all materials respond differently to agglomeration, testing is often a necessary part of pin mixer process development and commercial unit design.

Through batch and pilot-scale testing, the process variables required to produce the desired result on a commercial scale can be determined. Process Engineers in the FEECO Innovation Center typically work with the following variables:

- RPMs

- Binder formulation

- Binder feed rate and spray location(s)

- Solids feed rate

- Particle size distribution

- System pressures

- Temperature

By working with these variables, numerous particle characteristics can often (but not always) be controlled; it should be noted that disc pelletizers (also known as pan granulators) offer a greater level of control over end product specifications. Depending on the characteristics of the material, qualities that may be controlled through adjusting parameters in the pin mixing process typically include:

- Attrition

- Bulk density

- Compression

- Crush strength

- Green/wet strength

- Flowability

- Physical characteristics

- Particle size distribution

- Solubility

- Temperature

Testing can be conducted on the pin mixer as a stand-alone device, or as part of a larger, continuous process loop integrating a disc pelletizer or drum agglomerator and dryer.

Conclusion

Pin mixers are essential in a number of modern industrial processes, providing an all-in-one processing solution to mix, pelletize, and densify fines into dust-free granules. Alternatively, the mixer can be used to carry out a single objective.

The pin mixer’s ability to achieve mixing, pelletizing, and densification in one machine is based on standard agglomeration principles combined with a unique zonal operating theory.

FEECO is the leading provider of tumble growth agglomeration equipment and systems. Our custom pin mixers are designed around the unique characteristics of the material to be processed and backed by our state-of-the-art testing facility. For more information on our pin mixers, disc pelletizers, or agglomeration testing capabilities, contact us today!