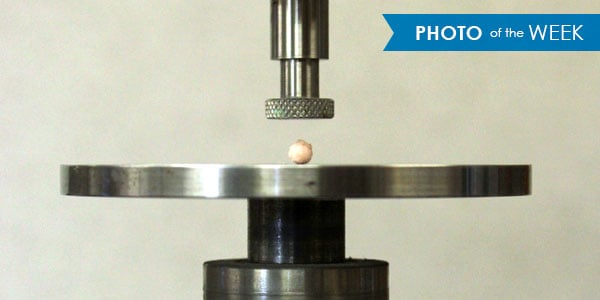

This week’s photo is a crush strength tester, a piece of equipment commonly used by Lab Engineers in the FEECO Innovation Center.

The crush strength tester determines how much weight, in pounds, a pellet can withstand before it breaks. The analysis provides significant value in regards to material handling, as pellets need a desired amount of strength to survive the remainder of processing and transportation. Additionally, the end use of a product will often require a particular crush strength, so it is frequently tested throughout processing to ensure pellets are meeting the desired requirement.

A pellet is placed on the center of the circular plate. A knob is turned, and the pellet comes into direct contact with the smaller, circular plate above it. The two plates create pressure on the pellet, ultimately crushing it and measuring how many pounds, point to point, it took to break.

Crush strength is just one of the many tests FEECO Lab Engineers perform when processing a material. For more information on FEECO’s lab testing capabilities, contact us today!