Phosphates can be made into an array of products, from fertilizers to animal feeds, and even consumer products. And while phosphate production is a well-established industry, process development services remain a critical component in the development of a successful phosphate plant, but are sometimes an overlooked tool in the producer’s toolkit.

FEECO recommends all phosphate producers, no matter what sub-sector they work in, leverage process development services when building or modifying a phosphate plant.

Why Process Development is Important With a Phosphate Plant

There are many reasons why testing is both necessary and desirable when it comes to new and existing phosphate plants.

In Creating a New Product or Process

New phosphate products are constantly being developed in all sectors. When manufacturing phosphoric fertilizers, it is common to try new blends for custom applications. Similarly with phosphoric animal feed production, producers often test new products aimed at better nutrition. Testing is also used with consumer products to develop new detergents, cleaners, and other products for consumer use.

In creating a new process or product, process development testing serves as the foundation of a successful phosphate plant, establishing basic process and feedstock parameters and helping producers to move through the scale-up process more smoothly and with lower risk. This is particularly true when working with a novel source material, trying a new formulation (which could affect the granulation process), or when looking to consistently produce product according to rigid quality specifications, among other settings.

When Improving an Existing Product

The improvement of an existing product is perhaps the most common way producers can take advantage of process development services. When new market opportunities open up, or a product isn’t performing as intended (or could perform better), a variety of characteristics can be modified to improve performance or enhance the product in some way.

Testing in this setting is essential in revealing the process and material parameters necessary to produce the desired results, without affecting the live production environment or putting existing production commitments at risk.

Producers can lean on process development services to streamline their efforts when looking to adjust the blend or formulation of a product, alter physical characteristics such as granule size, crush strength, or bulk density, or to improve product handling and performance qualities.

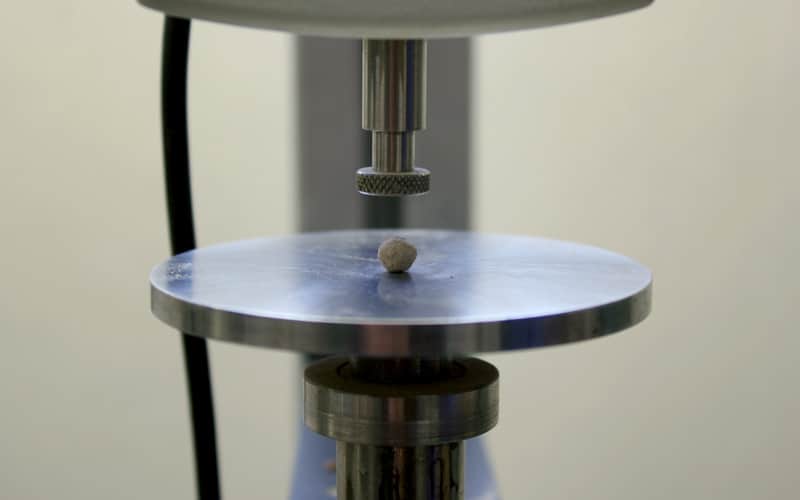

A crush strength test is carried out on a granular phosphate fertilizer

When Improving an Existing Process

Process development testing is also an excellent option when producers are looking to improve on their existing process. They can take advantage of process development services to troubleshoot an inefficient production line, work out the incorporation of a new addition to the process, or even test out an improved way of carrying out production. Again, this can all be carried out without affecting the live production environment or impacting production schedules.

A thorough process testing and development program ultimately helps to de-risk the commercialization process, whether developing an entirely new plant, improving an existing one, or enhancing the way a product performs or handles.

What Types of Testing are Available for a Phosphate Plant?

The FEECO Innovation Center offers several methods and equipment for testing the production of phosphate products:

Granulation (Agglomeration)

Granulation of phosphate products is frequently tested in the Innovation Center for both fertilizer and animal feed applications. The FEECO Innovation Center can accommodate the use of phosphoric acid, sulfuric acid, or ammonia, allowing various reactions in the granulation process to be tested. All pumps, spray systems, heat tanks, and granulation equipment are designed to handle both heated and non-heated phosphoric acids and gases.

Testing may also include evaluating the feasibility of utilizing or incorporating a novel source material for granulation, such as ground ore fines, or recycle or baghouse fines, in order to recover value from a waste or process byproduct.

The disc pelletizer shown here is frequently used for testing wet granulation of phosphate products.

Drying & High-Temperature Thermal Testing

Phosphate rock varies considerably in chemical composition and the materials that it is found with from one deposit to the next, and even within the same deposit. This presents challenges when looking to process the phosphate rock, because few samples are alike, making testing a necessity.

Phosphate rock may be upgraded in a rotary kiln to accomplish a variety of goals. Phosphate materials also frequently require processing in a rotary dryer to remove moisture and meet market expectations and producer specifications.

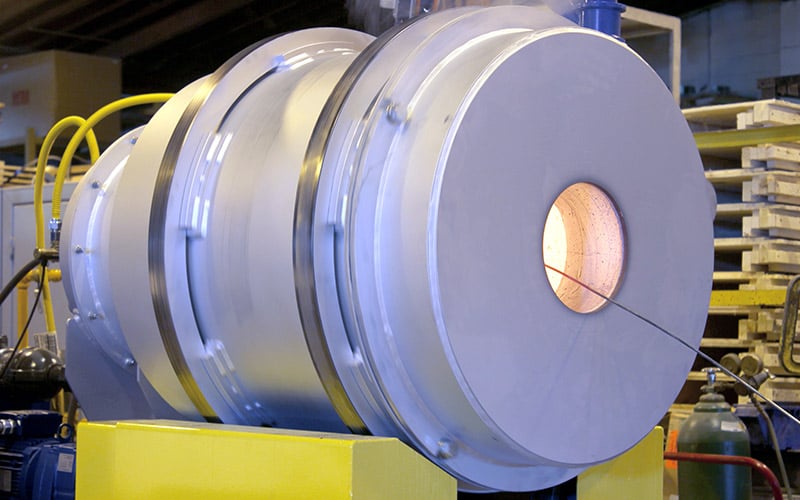

Direct-fired batch kiln used for testing in the Innovation Center

For these reasons, thermal testing in a kiln or dryer, depending on the goal, is often conducted in the Innovation Center to determine the time and temperature profiles required, as well as collect emissions data and establish the parameters needed to produce the desired results. This not only aids in designing a process that most efficiently processes the material, but it also helps in the engineering of a commercial size unit.

Depending on the goal of testing and what information the customer already knows, testing may start out at batch scale, with small samples of material being tested to gather initial data and determine feasibility of the intended goal. Once batch testing has been successful, continuous pilot-scale testing can be conducted. This is a much larger-scale test, where the process is tested as a continuous process loop.

Fluid bed dryer testing is also available as an alternative approach to drying.

The Innovation Center’s test fluid bed dryer

Advantages to Testing with FEECO

Testing in the FEECO Innovation Center offers unparalleled advantages to customers.

Our extensive history in fertilizer and agriculture brings our customers unmatched expertise. Combined with the unique capabilities of our testing facility and our ability to test nearly any phosphate-based process, FEECO has become the epicenter of process development for phosphate plants, helping our customers to reduce investment risk. We can work with you to take your project from idea to full-scale production, and even manufacture the equipment required to do the job.

Conclusion

Process development is a critical part of the success of many phosphate processes. FEECO has been helping companies to create custom fertilizer and animal feed products since 1951. For more information on testing phosphates in the FEECO Innovation Center, contact us today!