The recent introduction of the Agriculture Environmental Stewardship Act of 2017 could mean big changes are ahead for the agriculture industry.

The bill, which would incentivize the development of biogas and manure nutrient recovery systems, was proposed by Congressman Ron Kind, D-Wisconsin, and Tom Reed, R-NY and has already seen encouraging bi-partisan support.

Overview of the Legislation

Companion legislation to Senate bill 988, the Act would provide energy tax credits through the year 2021 for qualifying biogas and nutrient recovery systems. Legislation already exists as part of the federal tax code to provide a 30% tax credit toward capital costs for biogas facilities. However, it applies only to those that utilize biogas for electricity production, negating the other valuable benefits these systems have to offer and inadvertently discouraging farmers from implementing such a technology due to a high barrier to entry. The Agriculture Environmental Stewardship Act seeks to modify this legislation to open eligibility up to manure nutrient recovery systems as well.

While some farms already have digesters to produce biogas, this could prompt them to implement a downstream nutrient recovery system to produce additional products. Similarly, for those that may have the capacity to support such an operation but were discouraged by the capital costs, the valuable technology may now be within reach.

This has created some exciting buzz, as it would solve a number of problems both in and out of the agriculture industry.

The Need for Legislation Aimed at Biogas and Nutrient Recovery Systems

Many factors contribute to the need for legislation aimed at these vital technologies. The key driving factors include:

An Escalating Imbalance of Nutrient Resources

In recent years, concern has been mounting over the growing issues surrounding nutrient runoff, which can have a variety of detrimental effects on local ecology. Nutrient runoff occurs because plants only utilize what is needed (and is readily available for plant uptake). Some of the remaining nutrients are discarded and ultimately wasted in the form of runoff.

While there are many contributing factors to nutrient runoff, including soil conditions, distance to water bodies, weather patterns, and more, there are things that can be done to help prevent it. Modern nutrient management programs focus on reducing the opportunity for runoff to occur by mitigating circumstances within our control that may foster runoff. This includes over application of nutrients (manure or fertilizer), appropriately timed applications, as well as the growing trend of precision agriculture, which addresses in-field variability to deliver the right amount of nutrients only where needed and nowhere else.

Nutrient runoff from agriculture is largely being blamed for growing dead zones – hypoxic areas that cannot support aquatic life in water bodies. This has put pressure on large-scale farms, now the agricultural norm, to better manage their manure to reduce nutrient runoff. But, with the dwindling availability of land for application, coupled with the high cost of transporting manure, farmers are running out of places to put it.

This creates a problem, as manure is rich in valuable nutrients and organic matter, but can be detrimental if used where it is not needed.

At the same time as nutrients are going to waste and causing ecological damage, we’re also seeing areas where nutrients are lacking. These excess nutrients could be processed into a granular product and used elsewhere to fulfill nutrient needs, creating a more balanced system of nutrients.

A Desire for More Renewable Energy

According to the Biogas Opportunities Roadmap by the USDA, USEPA, and USDE in 2014, a fully realized biogas industry could not only reduce methane emissions, but could also offer a boost to the economy, and provide a source of renewable energy.

According to the report, if fully realized, the estimated potential of the US biogas industry could produce enough energy to:

- Keep more than 3 million Americans homes out of the dark.

- Reduce methane emissions equivalent to 4 to 54 million metric tons of greenhouse gas emissions in 2030, the annual emissions of between 800,000 and 11 million passenger vehicles.

- Provide economic benefits as follows: $3 billion in capital deployment for construction activity resulting in approximately 275,000 short-term construction jobs and 18,000 permanent jobs to build and run digesters (not including energy and product sales and potential environmental credits).

A Need to Reduce Greenhouse Gas Emisions

According to the EPA, in 2015, agriculture accounted for about 9% of total U.S. greenhouse gas emissions. Greenhouse gases in agriculture are produced through a variety of sources, including the cultivation of nitrogen-fixing crops, irrigation practices, and even through livestock themselves, among other things. One source that has received increasing attention is the management of manure.

In the past, manure has generally been managed through the use of lagoons and other storage systems. But these systems produce greenhouse gases that are then allowed to escape into the atmosphere. In an effort to reduce the release of these gases, farms have been implementing anaerobic digesters.

Anaerobic digesters use a controlled environment to promote the breakdown of organic materials through microbial action in the absence of oxygen. This biological process produces methane which can then be captured and converted into a usable source of energy. This reduces the contribution of greenhouse gases that would otherwise have been released.

In 2008, the dairy industry set a voluntary goal of reducing emissions from fluid milk by 25% by the year 2020 – a goal that has since been supported by a number of initiatives, one of which is Dairy PowerTM, which aims to increase the use of on-farm anaerobic digesters.

What this Legislation Could Mean

While the benefits and problem-solving potential of these systems are well established within the agricultural community, significant barriers have stood in the way of progress. Not surprisingly, the most significant challenge has been the cost associated with implementing such systems.

The proposed Agriculture Environmental Stewardship Act would reduce the capital cost of biogas and nutrient recovery systems, decreasing the barrier to entry and allowing farms to adopt the technology. This has the potential to give the agriculture industry (and more) a major boost, both economically and sustainably through numerous benefits:

Improved Nutrient Management and Decreased Runoff

The implementation of these systems would make nutrient management practices much easier to follow. Improved nutrient management helps to reduce runoff, ultimately improving local water quality. In an article for Biomass Magazine, Jim Mulhern, president and CEO of the National Milk Producers Federation, had this to say:

“By creating incentives to make biogas and manure resource recovery technologies more affordable the Agricultural Environmental Stewardship Act will encourage more widespread use of manure digesters. This benefits society by decreasing nutrient runoff in waterways, decreasing farm odors, and improving water quality.”

In the same article, Patrick Serfass, executive director of the American Biogas Council, spoke on the topic as well:

“For a healthy economy, we need healthy soils and clean waterways. Biogas and nutrient recovery systems help us achieve cleaner, healthier soil and water and the Agriculture Environmental Stewardship Act will increase the deployment of these systems.”

Improved On-farm Economics

The implementation of biogas and nutrient recovery systems also hold potential for improving on-farm economics in the following ways:

- Farms can supply their own source of sustainable nutrients, reducing the need to purchase additional fertilizers.

- Recovered nutrients can serve as an additional source of revenue, especially when processed into a granular fertilizer product.

- Dried digestate fiber can serve a bedding supply, allowing farmers to stop purchasing bedding from external sources. In some cases, the use of dried manure solids as a bedding may even improve milk quality in dairy cows, further improving the bottom line.

- Biogas can serve as a source of energy to power on-farm operations, and in cases where excess energy is produced, can be sold back to the grid for additional revenue.

Granular manure fertilizer created in the FEECO Innovation Center

How Biogas and Nutrient Recovery Work Together

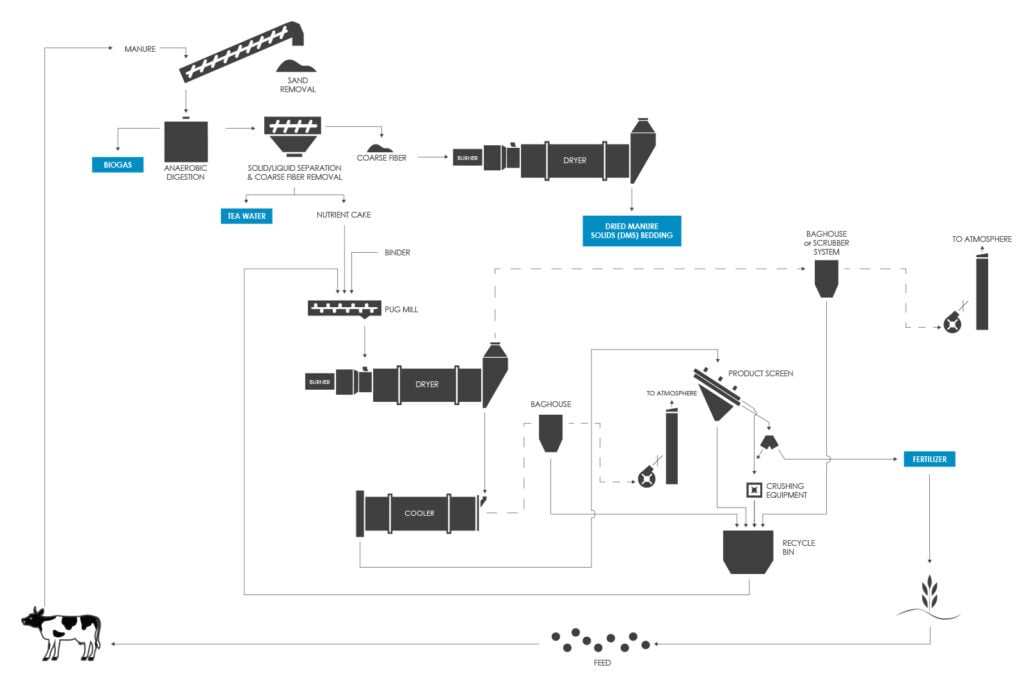

In our recent article, The Future of Farming: An Integrated Approach to Manure Management, we detailed the process of the potential for a closed loop approach to manure management, in which biogas, dried manure solids (DMS) bedding, irrigation water, and a granular fertilizer product are produced. The effects of this approach are summarized in the illustration below.

Impact on Wastewater Treatment Plants

Biosolids, or treated sewage sludge from wastewater treatment facilities, has seen increased attention in the news in recent years, as municipalities also feel the pressure of effectively and sustainably managing an increasingly regulated material.

While the legislation does not directly address nutrient recovery in relation to wastewater treatment systems, it is still likely an important step in an effort to bring widespread use of such technology to this sector as well.

Conclusion

The Agriculture Environmental Stewardship Act could be a critical component in advancing the agriculture industry both sustainably and economically, as well as in alleviating current industry challenges. Given the support this bill has already seen, the future looks promising for biogas and nutrient recovery.

As a veteran of the fertilizer industry, FEECO has worked on many of the projects pioneering the implementation of such technologies, helping farms to process their recovered nutrients into premium fertilizer products, and digestate into dried manure solids (DMS) bedding products.

We offer feasibility testing, process development, custom equipment design and manufacturing, as well as install and parts and service support. For more information on our capabilities, see our resources below, or contact us today!

Related Resources:

Nutrient Recovery (6295 downloads )Benefits of Granulation Infographic

Bedding Recovery Project Profile

Granular Fertilizer Systems (10353 downloads )