The FEECO pin mixer offers a preventive approach to managing coal dust.

Despite efforts to move away from fossil fuels, coal is still an important energy source and will likely continue to remain so well into the future. Unfortunately, with coal comes coal dust – a challenging and unavoidable by-product of the industry which presents a number of issues that have made dust control a top priority. The pin mixer continues to be a favored approach for several reasons.

Why Coal Dust is a Problem

The dusty nature of coal is problematic in numerous ways. Not only is it a nuisance, but it also presents a hazard; aerated coal dust is highly susceptible to spontaneous combustion with potentially devastating results. It is also recognized as a hazardous inhalant for workers.

Furthermore, coal dust is incredibly challenging to handle, not only causing dust issues, but also the potential to build up and clog mechanical components in surrounding machines. It can also affect the bottom line in the form of product loss.

As a result, the industry puts a significant focus on managing coal dust. One of the most common methods used to manage the dust has been through conditioning in a FEECO pin mixer.

Pin Mixer Operation

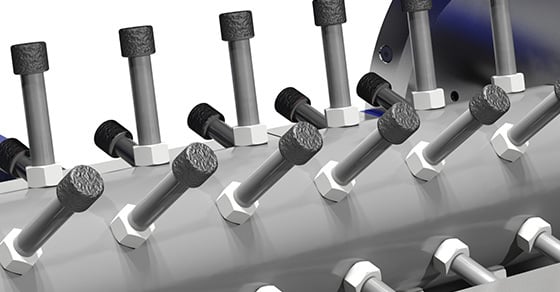

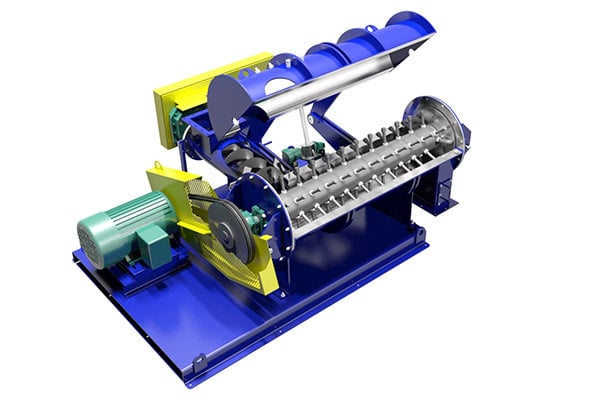

3D Model of a FEECO Pin Mixer used for coal dust conditioning

Consisting of an axial rotor with numerous adjustable pins (rods) extending from it within a stationary cylindrical housing, the device uses centrifugal force imparted by the shaft, which spins at several hundred RPMs. A liquid injection pump, or spray system, meters in the desired water or chemical binder(s) at the appropriate rate to provide uniform wetting.

Once the fines and liquid have been thoroughly mixed, the particles are then pelletized into small agglomerates, with the intensity of the centrifugal force eliminating air and reducing water volume. This is ideal from a burning standpoint, as often times, once coal dust is conditioned, it can be put back into the coal-burning process as recycle. The use of centrifugal force to densify the particles also minimizes the amount of liquid binder required.

The result is a conditioned, de-dusted coal that is easily handled, transported, and reintegrated into the production process. This method has been so effective, that throughout our extensive history, we have provided nearly one hundred pin mixers to the power generation and pulp & paper industries.

Coal dust after conditioning in a FEECO Pin Mixer

Conclusion

Coal dust is a challenging inevitability of working with coal, causing handling issues, lost product, and safety hazards. While other options for de-dusting coal are available, the industry has largely come to rely on FEECO pin mixers for mitigating dust issues.

Through centrifugal force, pin mixers provide an optimal coal conditioning system while minimizing binder use. FEECO has been the industry’s preferred provider of these robust machines since 1951. For more information on our pin mixers, contact us today!