Top Applications for Rotary Kilns

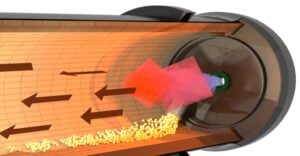

Rotary kilns (also known as rotary calciners) are used to heat solids to a predetermined temperature in a controlled processing environment in order to create a chemical and/or physical reaction. While rotary kilns have long been used in producing cement, their flexible capabilities have extended …