Many factors are taken into consideration when designing a rotary kiln. Each affects the ability to produce a desired chemical reaction/phase change in an efficient manner. Characteristics such as bulk density, specific heat, and flowability, among others, all interact to influence how the material will respond to processing, and subsequently, how the kiln will need to be designed around those characteristics to produce the desired result. One critical factor in designing a rotary kiln is the air flow configuration, or the direction in which the process gas flows through the kiln in relation to the material.

Rotary Kiln Air Flow Configurations

Direct-fired rotary kilns are available in two types of air flow configurations: co-current and counter current. Both options have been developed through extensive research and development in order to maximize the thermal efficiency of the process. During the design process, the selection of which air flow configuration will best suit the application is based on the material’s properties, as well as overall process requirements. Because of this, it is important to understand how each air flow option functions to fully understand the benefits each has to offer.

Co-Current Air Flow

Co-current air flow, which is also referred to as parallel flow, occurs when the products of combustion flow in the same direction as the material. This immediately puts the coldest material in contact with the hottest gas in the kiln, resulting in a rapid initial temperature change. For this reason, co-current kilns work best with materials that do not need a gradual temperature increase for a controlled transformation. An organic combustion process commonly uses this air flow configuration, because it does not require a very specific end product. In this example, a waste material (e.g. landfill product) containing both organic and inorganic material is introduced into the kiln. These materials can come into immediate contact with the high heat and the kiln can facilitate the phase change very early on in the process. The organic material is burned off with the high heat and what is left is a dry ash.

Counter-Current Air Flow

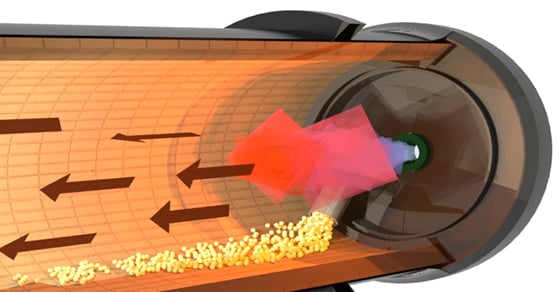

Counter-current air flow is when the air flows in the opposite direction of the material flow. In this design, the material is heated gradually while traveling through the kiln. In this configuration, the material comes in contact with the hottest products of combustion just before discharge. The main benefit to this air flow configuration is the thermal efficiency; with the burner being mounted at the end of the thermal processing cycle, less heat is required, resulting in decreased fuel consumption. This is illustrated in the tables below.

The co-current configuration needs a much higher initial temperature to heat the process material from its initial temperature and get the desired phase or chemical change. In contrast, in a counter-current configuration, the material and the process gas temperature are directly correlated; the air flow (process gas) temperature only needs to be slightly higher than the required temperature for the material transformation. The result is a lower burner temperature and reduced operating costs.

Additionally, the counter-current design is commonly used for a more controlled phase or chemical change, where the material temperature needs to be gradually increased to achieve the desired end result. Heat hardening is a common process that utilizes the counter-current air flow to maintain a controlled phase change. The gradual, yet extreme heating process allows for a material such as a proppant to transform into a much harder material.

Understanding how each air flow system works is one of the many considerations in designing the most efficient and effective rotary kiln for the job. Both air flow configurations have their unique and varying benefits for material transformation. FEECO encourages that each material goes through a research and development process at our on-site testing facility, The Innovation Center. The information gained through FEECO’s proven testing procedures allows us to design the most efficient and beneficial rotary kiln for our customer’s material requirements. For more information on our custom rotary kilns or testing capabilities, contact us today!