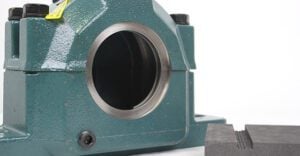

Photo of the Week: Trunnion Skewing Adjustment

This week’s photo highlights a trunnion skewing adjustment in action. A dial indicator (bottom left of photo) is used to measure the movement of the trunnion wheel bearings. If the bearings are not positioned correctly, they should be adjusted. The purpose of the trunnion skewing …