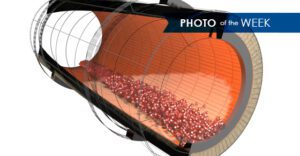

Photo of the Week: Interior of a Batch Rotary Kiln

This week’s photo highlights the interior of a batch rotary kiln. The rod-like structures at the bottom of the image (labeled “C”) are two thermocouples. They are typically used in the kiln to measure bed and exhaust gas temperatures. The upper rod is an airline …