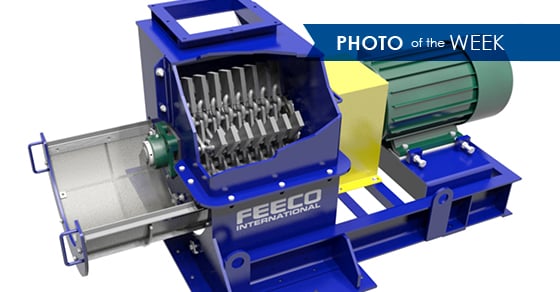

This week’s photo is a hammer mill in 3D.

The FEECO hammer mill is designed to reduce dry and semi-moist materials, specifically granulated or pelletized materials, to the product range of minus 4 mesh to plus 20 mesh. Commonly processed materials include aggregates, minerals, ores, and fertilizers.

How do hammers mills work? FEECO’s double rotor hammer mill uses a central rotating shaft, fastened with “hammers” on pivots attached to the shaft. When the shaft spins, the hammers swing and collide with the material, causing it to break into smaller pieces.

The benefit of selecting a FEECO hammer mill include:

- Simplified maintenance

- High throughput

- Non-clogging design

- Easy access

- Use of a cracking action instead of grinding or pulverizing

Contact FEECO today to see if the hammer mill is right for your size reduction requirements.