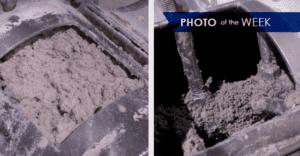

Photo of the Week: Washboarding on a Rotary Drum Tire

This week’s photo highlights washboarding on a rotary drum tire. Washboarding is indicated by the vertical grooves that extend the length of the tire, and it is caused by abnormal skewing of the trunnion wheels, or trunnion wheel mis-alignment. FEECO offers a tire grinding service …