BUCKET ELEVATORS

As a leading supplier of bulk material handling equipment and conveyor systems, we offer a wide variety of bucket elevator models to elevate bulk products ranging from dry, dusty powders such as fly ash, to heavy solids such as iron ore pellets.

Bucket elevators can be manufactured in a number of configurations, including centrifugal belt, centrifugal chain, continuous belt, continuous single chain and continuous double chain. All FEECO elevators are built around the specific characteristics of the material (bulk density, particle size distribution, temperature, etc.), as well as the required horsepower and height, for an efficient and effective vertical transport solution that offers superior handling.

FEATURES

- Removable top covers

- Access doors for easy maintenance

- Horizontally and vertically heavy-reinforced, jig welded head, boot, and intermediate sections

- Adjustable throat plate at discharge

- Inspection doors on both sides of discharge

- Service platforms and access ladders available

- Heavy-duty, robust construction

- Custom design

- Various bucket designs available

- Robust bearings, pulleys, and drive options

- Optional variable frequency drive (VFD); our elevators can be connected to plant-wide VFD’s or we can supply a remote/panel-mounted VFD, which is beneficial for maintenance and “creep control.”

CONFIGURATIONS

Bucket elevators are available in either the centrifugal or continuous configuration. For both options, the elevator can be either the belt or chain type.

CENTRIFUGAL

Centrifugal bucket elevators are chosen when there is a need to move large tonnages quickly. Instead of direct loading, buckets serve as the loading apparatus, scooping material up from the boot or inlet section. For this reason, durable buckets are recommended with this design.

Centrifugal force at the head pulley “throws” material from the buckets into the discharge chute. The buckets are spaced in wider intervals to prevent discharge interference from the preceding bucket and to assure maximum fill of the buckets at the boot end while moving at a higher speed. The design of this style yields optimized fill and reduced interference between buckets.

Centrifugal style elevators are ideal for applications like sand, gravel, wood chips, and other free-flowing bulk solids where fragility is not a concern.

CONTINUOUS

Continuous bucket elevators are designed for more gentle handling requirements and are often used in applications working with friable, fragile materials where minimal product degradation or damage is a priority. They are also ideal for sluggish or abrasive solids, as well as light, free-flowing matter where aeration must be avoided.

Material is fed into the buckets from an inlet chute. Buckets are designed for gentle continuous discharge; the buckets are closely spaced on the belt or chain to allow the material to flow over the backside of the preceding bucket, whose extended sides form a chute to guide the material into the discharge spout. Direct loading, combined with the slow speed of this elevator type, avoids the “throwing” action associated with centrifugal style elevators, making it ideal for use with fragile solids.

BELT Bucket Elevators

Belt elevators offer a cost-effective approach for lighter-duty jobs. Buckets are mounted onto a belt made of various compounds depending on the application.

The belt design is ideal in settings where noise is a concern, as this approach offers quiet operation.

CHAIN bucket elevators

Chain elevators provide a higher-capacity, more durable option. They are best for jobs requiring rugged handling of large particles, or materials that are heated or have a potential for combustion.

BUCKET STYLES

Buckets are available in many shapes, sizes, and materials. Options differ depending on whether the unit is continuous or centrifugal. FEECO offers the following bucket styles:

- Style AA (Centrifugal)

- Style AC (Centrifugal)

- Medium Front (Continuous)

- High Front (Continuous)

- Super Capacity (Continuous)

For additional information on bucket styles, see Bucket Style Selection.

BUCKET ELEVATOR ADVANTAGES

Bucket elevators are the preferred choice for vertical conveying applications in a range of industries for the many advantages they offer.

INDOOR OR OUTDOOR vertical HANDLING

Bucket elevators are enclosed systems, making them ideal in both indoor and outdoor operations, as well as when dust is a concern; in addition to providing structure, the casing efficiently protects and contains the solids within.

CUSTOMIZABLE

FEECO elevators are highly customizable, allowing for design of a system tailored to the specific challenges and goals of the project.

SMALL FOOTPRINT

Bucket elevators have a significantly smaller spatial footprint compared to inclined conveyors.

DIVERSE

Bucket elevators are capable of carrying a wide range of bulk solids, from heavy rocks to light and fluffy free-flowing materials.

HIGH CAPACITY

Bucket elevators are capable of carrying large volumes of material. The actual TPH throughput capacity of the elevator depends on the characteristics of the material.

FEECO is capable of meeting the requirements necessary for CE marking equipment.

All FEECO equipment and process systems can be outfitted with the latest in automation controls from Rockwell Automation. The unique combination of proprietary Rockwell Automation controls and software, combined with our extensive experience in process design and enhancements with hundreds of materials provides an unparalleled experience for customers seeking innovative process solutions and equipment. Learn more >>

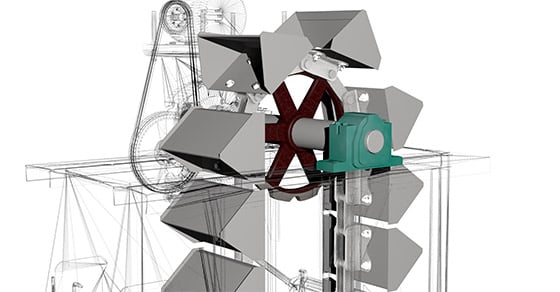

BUCKET ELEVATOR COMPONENTS AND PARTS

The image below shows the standard components of a bucket elevator. A full range of customizations are available to increase the flexibility and performance of the unit in its intended application. Click image to view larger.

Mechanical Construction of a Bucket Elevator (3D Bucket Elevator by FEECO International)

A – Head Pulley Assembly

B – Head Pulley

C – Drive Motor

D – V-Belt Drive

E – Gear Reducer

F – Heavy-Duty Roller Bearings

G – Maintenance Platform

H – Ladder with Safety Cage

I – Inlet/Feed Chute

J – Boot Pulley Assembly

K – Screw Take-up Assembly

L – Pillow Block Ball Bearing

M – Elevator Casing

N – Belt & Bucket Assembly

O – Discharge Chute

APPLICATIONS

Bucket elevators are employed in many different industries and applications, from chemicals and agriculture settings, to mining, and everything in-between. Generally, they are not suited for wet, sticky materials, or those that are stringy or tend to mat or agglomerate. They are frequently found in bulk material handling systems at power plants, fertilizer plants, pulp & paper mills, and steel production facilities. Some of the most common applications for which bucket elevators are employed include:

- Aggregates

- Animal Feeds

- Calcined Coke

- Coal

- Fertilizer

- Fly Ash

- Frac Sand

- Glass products

- Minerals

- Potash

- Lime

- Wood Chips and other wood products

Not sure if a bucket elevator is right for your project? Contact us today: We can guide you through the process of evaluating the bucket elevator as an option, as well as selecting the most appropriate configuration.

SELECTING THE RIGHT BUCKET ELEVATOR MANUFACTURER

Identifying the right bucket elevator supplier for a job can be a daunting task. To narrow the potential suppliers, consider the following factors:

Flexibility: Make sure the manufacturer is prepared to tailor the unit to the specific requirements of the material being conveyed, as well as any operational goals. This will ensure an efficient and reliable solution with long-term dependability.

Material Expertise: Many manufacturers specialize in a specific industry. In choosing a vendor, ensure they have experience around the unique challenges of the material to be handled.

Quality: Bucket elevators must be manufactured according to high quality standards for a low-maintenance, reliable handling solution.

Parts & Service Support: Select a supplier that has the capabilities to service and maintain their equipment for a maximum return on investment. This includes provision of spare parts, training, installation assistance, and more.

For more information, see our article Choosing a Bucket Elevator Manufacturer.

RESOURCES

Bucket Elevator ARTICLES

Agricultural vs. Industrial Bucket Elevators: Why the Right Choice Matters

Confusion often arises when sourcing a bucket elevator, with prices varying widely from one supplier to the next. The reason? The …

Bucket Elevator Design: Centrifugal Vs. Continuous

The choice between continuous and centrifugal bucket elevators is the starting point for bucket elevator design, with implications on each decision …