Elevating Efficiently: Bucket Elevator Drive Assembly Options

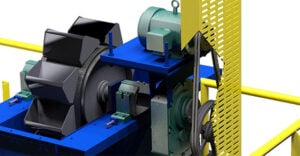

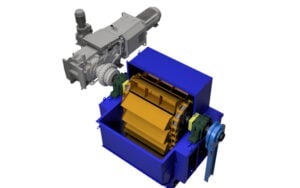

The drive assembly is a critical consideration in the design of a bucket elevator, with the potential to impact both productivity and equipment service life. The following covers the different configurations, their advantages in different settings, and optional modifications. Drive Assembly Options for Bucket Elevators …