EQUIPMENT

Many of the animal feed industry’s largest producers rely on FEECO expertise for their animal feed production needs. We provide custom equipment for mixing, granulating, and drying everything from premixes and concentrates, to supplements, minerals, additives, antacids, and more. Common applications for FEECO equipment in the animal feed industry include:

- Corn gluten

- Feed-grade phosphates (MCP, DCP, DFP)

- Fruit pomace

- Insect larva

- Limestone

- Monosodium phosphate

- Phosphate rock

- Urea

- Salts

- Sodium butyrate

- Sugar beet pulp (cossettes)

FEED PROCESSING

Animal Feed Granulation with a High-Speed Mixer

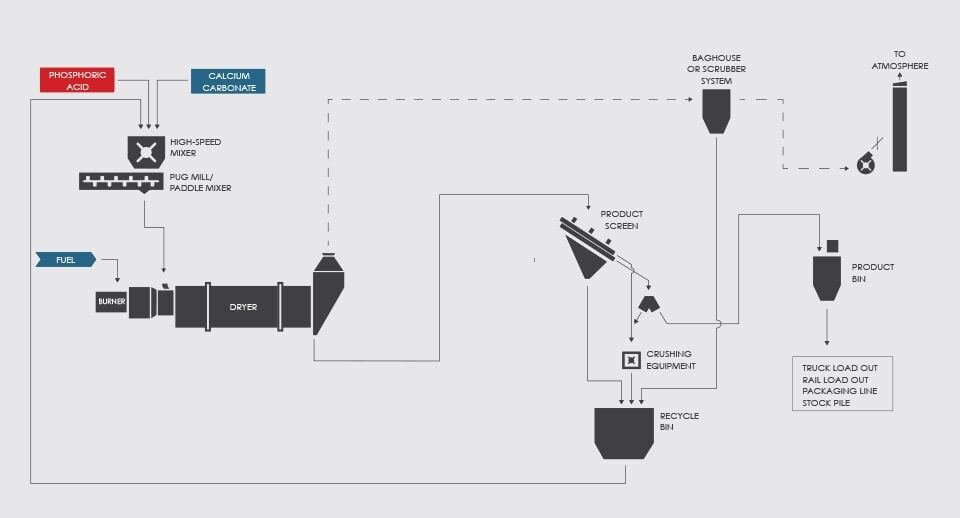

Our proprietary approach to the granulation of feed-grade phosphates such as Mono-Calcium Phosphate (MCP), Di-Calcium Phosphate (DCP), and De-Fluorinated Phosphate (DFP) greatly improves upon the traditional approach to granulation.

Through the use of our high-speed mixer as a pre-mixing step, a more intimate mixture of the feed materials is created, resulting in a more thorough reaction and subsequently, improved product characteristics, including greater uniformity and crush strength.

Granulation systems can be provided for capacities up to 50 MTPH and can be automated with a PLC-based control system, motor control center (MCC), and instrumentation.

Continuous Feed Mixers

In addition to our high-speed mixer, FEECO offers two kinds of mixers ideal for accomplishing different objectives in animal feed processing: pin mixers and pugmill/paddle mixers.

Pin mixers are ideal for combining fines with a liquid additive to produce a homogeneous blend of components and can even produce de-dusted micro pellets.

Our pugmill mixers are the preferred device for the production of MCP, DCP, and DFP, particularly when combined with our high-speed mixers. The dual, counter-rotating shafts yield a kneading action that not only ensures a complete reaction between components, but good agglomeration as well.

Animal Feed Dryers & Coolers

Our custom rotary dryers and coolers are designed around the feed to be processed in order to meet moisture content and temperature objectives as efficiently as possible. Fluid bed dryers are also available.

Pelletizing & Coating

In addition to our mixer granulation systems for phosphate feed additives, we also offer a range of agglomeration equipment for converting powdered or crushed feed components into a premium granular product. This includes disc pelletizers, granulation drums, and coating drums.

Rotary Kilns for Upgrading Phosphate Ores

When phosphate ores become challenging to upgrade via mechanical means, FEECO rotary kilns are ideal for separating carbonates, decomposing organic components, and removing fluorine, as well as nodulizing ore in preparation of conversion to elemental phosphorus.

BULK FEED HANDLING EQUIPMENT

FEECO also provides a comprehensive line of bulk material handling equipment for all of your feed handling needs. We offer custom bucket elevators, belt conveyors, reversing shuttle conveyors, and steep incline conveyors, along with pieces to increase the flexibility of your handling system, such as belt trippers and plows, and belt feeders.

We can supply a single piece of handling equipment to fit into your existing process, or a complete bulk handling system as part of an overall process solution.

PROCESS DEVELOPMENT SERVICES FOR ANIMAL FEED MANUFACTURING

The FEECO Innovation Center is a unique testing facility where we can test your material at both batch and pilot scale in order to work out process variables and design commercial-scale units, as well as scale up the process.

The FEECO Innovation Center is well equipped to suit a wide range of testing needs; we can test on a single piece of equipment, or combine multiple pieces of equipment into a continuous process loop.

We offer comprehensive testing services in four categories:

Feasibility/Proof of Concept: An initial, non-witnessed batch testing phase in which the possibility of creating a product is explored.

Proof of Product: A more in-depth batch testing phase in which more time is spent determining whether a product can be made to desired specifications.

Proof of Process: A continuous testing phase that aims to establish the equipment setup and parameters required for continuous production of your specific material.

Process/Product Optimization: An in-depth study to optimize your specific material’s characteristics and/or production parameters in an industrial setting.

Learn more about the Innovation Center >>

PARTS & SERVICE

FEECO provides a comprehensive offering of parts and service to keep your equipment running its best for years to come. This includes a variety of field services, process and equipment audits, spare parts, and more.

RESOURCES

PROJECT PROFILES

ANIMAL FEED GRANULATION ARTICLES

Phosphate Processing Equipment Overview

The phosphate industry continues to gain attention as of late, as the world begins to approach peak phosphorus. With that, companies …

Photo of the Week: High Speed Mixer

Today’s photo highlights a high speed mixer. FEECO’s high speed mixers are ideal for producing MCP and DCP animal feeds. They …