As populations increase, so does the need for resources, including metals such as nickel, silver, gold, copper, and uranium. However, it is not always economically viable to extract these metals from their low-grade ores. And now more than ever, recovering them from what is available to us, is of the utmost importance.

For this reason, the addition of a rotary drum agglomerator to the heap leaching process is increasingly beneficial, helping to maximize metal recovery.

What is Heap Leaching

Heap leaching is a process through which metals are extracted from the ore in which they are found. Heap leaching is often chosen for its efficiency and cost-effectiveness. As the need for resources increase, the heap leaching industry has risen to the occasion with advancements creating an even more efficient leach. One of which, is the process of agglomerating the ore prior to the leach.

How Heap Leaching Works

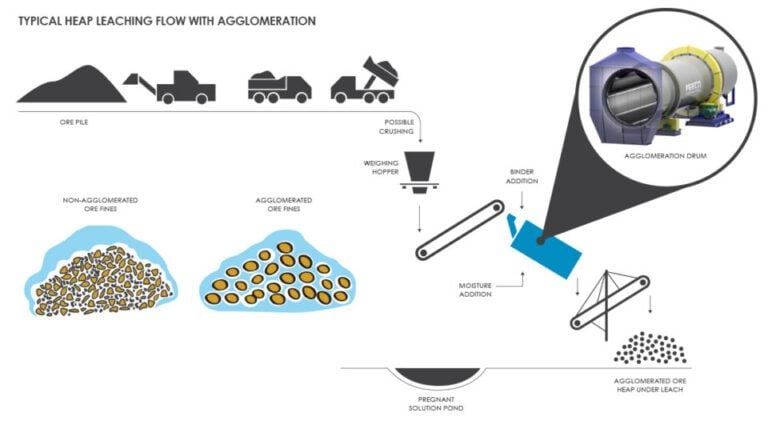

As seen in the flow chart below (figure 1), the ore, after being removed from the ground, is crushed down into fine particles. Traditionally, the fine particles would typically go from crushing straight to a heap, where leaching solution would be applied, and the metal would leach out. While this method is effective, its efficiency has been highly increased by the addition of a rotary ore agglomerator after crushing.

Incorporating Agglomeration into the Heap Leaching Process

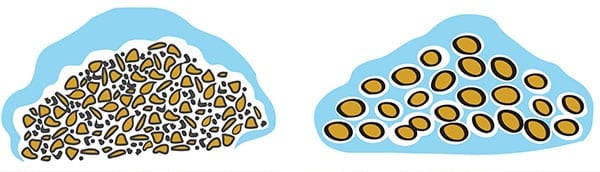

The agglomeration of the fines in the heap leaching process allows for enhanced, even percolation of a heap. If left untreated, smaller fines can accumulate in the spaces between larger particles, inhibiting flow of the leaching solution (see figure 2).

In addition to better percolation, adding a rotary drum agglomerator to the heap leach process also provides further leach effectiveness through the addition of the leaching solution in the rotary drum prior to the heap. This agglomeration pre-treatment homogeneously blends the binders and leaching solution with the ore prior to the heap, further increasing leach efficiency by jump-starting the leaching reaction and ensuring a uniform distribution of the leaching agent.

Pre-treating ore fines through agglomeration also de-dusts and improves bulk density to increase strength, allowing for larger heap piles and reduced crushing. Moreover, it creates a more porous material to increase flow rate and metal recovery, reducing leaching time and residual leach solution in the heap.

Adding a rotary agglomerator to the heap leach process is a dependable approach in getting the most out of a heap leaching operation.

FEECO has been custom engineering rotary agglomerators for over 70 years. For more information on our rotary drums, contact us today!