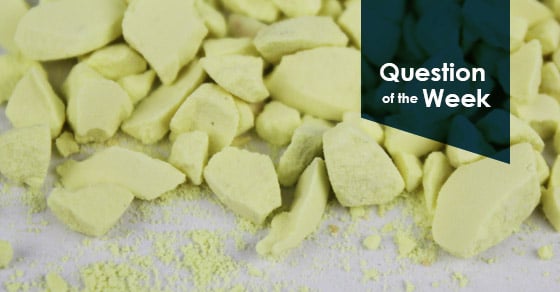

Attrition transpires when agglomerates break down into fines- an undesirable occurrence that results in excess dust and waste product. It is commonly seen with granules produced via compaction granulation, and is caused by the rough, jagged edges rubbing against one another and wearing down the edges.

Testing for attrition during the agglomeration product and process development stages is essential to creating the most ideal end-product. FEECO’s process experts in the Innovation Center are able to conduct such tests using an attrition tester– a machine that simulates the conditions under which granules rub together. On-size agglomerates are put into the machine, and once the test is complete, the sample is measured to determine what portion is still on-size. If too much attrition is occurring, adjustments can be made to the agglomeration process to help reduce it. This could include a number of things, from formulation change, to the addition of binder.

For more information on the challenges associated in agglomeration processing, download our Agglomeration e-book, or contact us today!