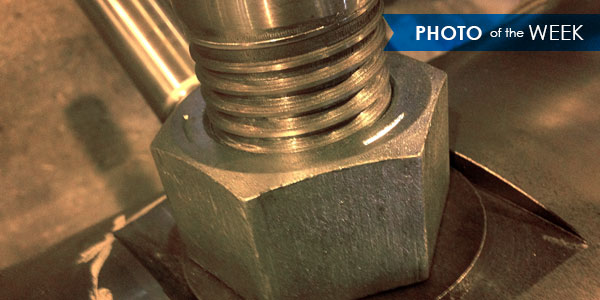

This week’s photo shows the base of a pin, the fundamental component of a pin mixer.

Pin mixers are industrial mixing devices that use rotational forces to blend, agglomerate, and condition fine materials. They rely on 3 main pieces of equipment for processing: an internal motor, shaft, and, of course, pins. Multiple pins are attached to the single shaft, and the shaft is continuously spun in the same direction via a motor. This combination thoroughly mixes materials, while also reducing water volume between particles, creating a densified agglomerate that can be dried and used as an end-product, or run through subsequent processing such as pelletizing on a disc pelletizer.

Pin mixers are a versatile piece of equipment; they can be used for pre-conditioning during a multi-step agglomeration process, or used as stand-alone agglomeration units. In addition, pin mixers are selected because they use less horsepower and binder than most other agglomeration equipment.

FEECO’s pin mixers are ideal for processing fly ash, dyes, fertilizers, coal dust, and many other materials. Could your material benefit from processing in a pin mixer? To find out, contact us today!