The push for a more circular economy continues to reinvent the definition of waste, with companies around the world coming up with creative waste recovery solutions that divert wastes from landfills and ensure critical resources remain in the supply chain.

As a leader in process development services and custom process equipment, FEECO has been assisting these companies in building the systems they need to convert their waste to value for decades. What follows are seven processes in which FEECO equipment can be used to facilitate waste recovery and reuse.

1. Converting Paper Sludge to a Soil Amendment

A byproduct of the paper industry, pulp and paper residuals such as waste paper sludge have typically been managed via landfill or incineration. Land applying this waste offers potentially significant benefits, but is made challenging because of the form the material is in, limiting the distance material can be trucked and presenting other challenges.

By drying the material and in some cases granulating it, producers can turn their waste into a more marketable soil amendment product. FEECO has extensive experience in facilitating the reuse of paper sludge and residuals through both drying and granulation.

Pelletized paper sludge produced in a pin mixer in the FEECO Innovation Center

Drying & Granulation Equipment for Paper Sludge Waste Recovery

Drying reduces the moisture content so that paper sludge is more manageable, reduced in volume, and appropriate for use as a mulch, carrier, or additive. The dried material may also be suitable for use as a pet bedding product.

Designed around the unique qualities of the specific source of paper sludge, a FEECO rotary dryer offers an efficient and reliable option in this setting.

Upon drying, granulation equipment can be employed to upgrade the material into a premium soil amendment or fertilizer product and allow for the inclusion of any nutrients or beneficial additives.

Depending on the desired product characteristics, one or more types of equipment may be used alone or in combination to create a granulation operation:

- Pin Mixer

- Pugmill Mixer

- Disc Pelletizer (Pan Granulator)

- Granulation Drum

A rotary dryer follows the granulation process to reduce the moisture content of the product to its final form for a stable, storable product.

2. Bedding Recovery from Manure

More and more concentrated animal feeding operations (CAFOs) are discovering the benefits in recovering value from manure by drying their manure solids (typically after processing in a digester) and utilizing them as a livestock bedding.

This not only provides a better bedding product in many cases, but it also alleviates the increasing strain around finding affordable, accessible, and effective bedding.

Rotary Dryers for Waste Recovery from Manure

FEECO has designed on-farm rotary dryers for this purpose, ensuring bedding is sufficiently dry to reduce bacterial content, without overdrying the material to the point that dust becomes a concern. This on-farm approach to manure management alleviates the pressure on farmers to manage increasing amounts of manure, while also adding value to the operation.

Manure-based livestock bedding during testing in the FEECO Innovation Center

3. Pyrolysis of Plastics

As the search for a solution to the plastics problem continues with mounting pressure, some companies are finding that the pyrolysis of plastics offers an effective approach not just to waste management, but also to resource recovery.

Through pyrolysis, plastics can be broken down into their original chemical building blocks, allowing them to be reused or even converted into a fuel.

Further, the approach can accommodate multiple types of plastic feedstock, and particularly those not suited to traditional mechanical recycling techniques, making this an essential tool in managing all types of plastic waste.

Waste Recovery Rotary Kilns for Plastic Pyrolysis

FEECO rotary kilns offer an engineered approach to high-capacity pyrolysis of plastics, with each kiln designed around the specific process and material goals. Producers also have the option to conduct process development testing in the FEECO Innovation Center to establish process criteria and data for the design of a commercial-scale rotary kiln.

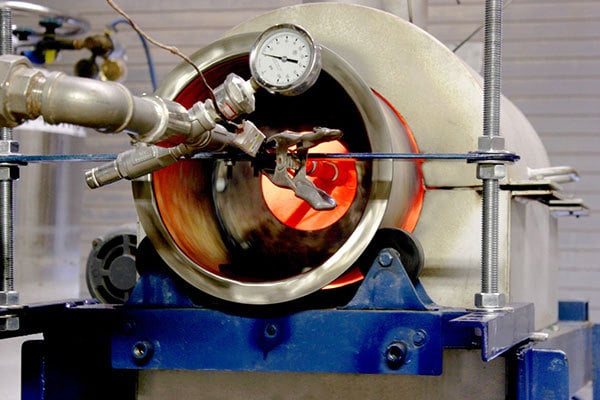

Indirect batch kiln used for testing in the FEECO Innovation Center

4. Chicken Manure Granulation

Granulation is becoming increasingly popular as a way to manage chicken manure and litter (among other types of manure) from concentrated animal feeding operations (CAFOs).

The practice converts an otherwise difficult-to-manage waste into a dry granular product that can be stored, sold, and transported much further than raw material.

Chicken Manure Granulation Equipment

FEECO is a preferred provider for testing services and custom granulation equipment in this effort due to our extensive background in converting organic wastes into premium fertilizer products.

As with paper sludge, the granulation process may vary, but typically includes the use of a pin mixer, pugmill mixer, disc pelletizer, granulation drum, or combination thereof.

Pelletized chicken litter

5. Spent Catalyst Recovery

The ability to recover spent catalysts represents a massive opportunity for the chemical industry; new catalysts are often a substantial cost in operating expenses, so producers typically do all they can to maximize the service life of their catalyst. At some point, however, the catalyst will become spent.

When catalysts have reached their loading capacity but haven’t undergone any permanent structural changes, thermal desorption, an advanced thermal treatment, can be employed to regenerate the catalyst so it can be used again.

Thermal desorption volatilizes the undesirable compounds, leaving only the catalyst material behind. This practice is especially attractive in the petrochemical industry where spent catalysts are subject to stringent disposal standards.

Rotary Kilns for Spent Catalyst Recovery

As a leader in custom rotary kilns, FEECO can engineer rotary kilns for facilitating a controlled processing atmosphere based on the type of catalyst and the volatiles present.

6. Reusing Precipitated Calcium Carbonate/PCC (Spent Lime)

Precipitated calcium carbonate (PCC), also known as spent lime, from sugar beet processing operations is another industrial byproduct that represents waste management challenges in both cost and liability. While researchers and sugar producers have long explored alternative approaches to management, one that continues to look promising is the use of spent lime as a soil amendment or fertilizer input.

By pelletizing precipitated calcium carbonate, sugar producers can create a saleable, market-acceptable product, instead of incurring waste management costs.

Pelletizing Equipment for Precipitated Calcium Carbonate Waste Reuse

While process configurations can vary, the production of a premium soil amendment or fertilizer product is typically carried out using a pin mixer, disc pelletizer or granulation drum, and rotary dryer as the primary equipment. Drying is also required for pre-treatment of the material as well, as the material is typically too high in moisture content for use as a granulation feedstock.

FEECO equipment is the industry standard for the production of premium soil amendment and fertilizer products.

7. Iron Recovery from Red Mud

Red mud, also known as bauxite residue, is a byproduct of aluminum production that has long plagued the industry with waste management challenges.

Despite being a significant industrial waste stream, however, red mud actually contains a number of materials that are valuable, making it an attractive resource recovery opportunity. Numerous potential recovery and beneficial reuse options are being explored, with iron recovery via reduction roasting and magnetic separation being a promising technique.

Red Mud Resource Recovery Equipment

FEECO assisted one company utilizing this approach through process development work in our Innovation Center, followed by the design of a commercial-scale rotary kiln to carry out this waste recovery process.

Rotary kilns are a natural fit for red mud processing applications, due to their flexibility in carrying out chemical reactions on large quantities of material on a continuous basis.

Red mud samples shown at various stages of reduction during thermal testing in the FEECO Innovation Center

Conclusion

As waste recovery becomes a driving force behind every industry, numerous opportunities are available for recovering and reusing these hidden resources.

Through process development services and the design of custom process equipment, FEECO can support producers in their waste recovery efforts at every step of the way. For more information on our testing services or equipment, contact us today!