Agglomeration equipment such as pin mixers and disc pelletizers are essential components in industrial processing operations everywhere, converting powders to granules, conditioning dusty materials, and improving production processes.

Though not requiring replacement often, acquiring agglomeration equipment that performs as well or better than the existing unit(s) is critical to managing efficiency and upholding product integrity. In navigating the replacement process, consider the following factors for best results.

FEECO is the leading provider of custom tumble-growth (agitation/non-pressure) agglomeration equipment and systems. Our state-of-the-art testing facility allows us to evaluate intended processes at both batch and pilot scale. All FEECO equipment is designed around the specific characteristics of the material to be processed and backed by our Customer Service Team, which can provide everything from training to inspections and repairs.

Preparing for Replacement

No matter what type of agglomeration equipment or production line is concerned, being prepared is the first step to minimizing potential downtime and avoiding a scramble for new equipment. As such, plant managers should take a proactive approach to replacing equipment, as opposed to waiting for a catastrophic failure to occur.

Knowing When it’s Time to Replace Agglomeration Equipment

Most problems with agglomeration equipment are generally reparable, but at some point, replacement is inevitable. While they can vary significantly, signs that can indicate replacement might be on the horizon include:

- Frequency of repairs on the rise

- Significant reduction in efficiency

- Inability to reach rated capacity

- Excessive vibration

If equipment integrity is in question, it is best to conduct an equipment audit. An experienced customer service engineer will review the technical data for the unit, along with its mechanical condition, to evaluate whether or not replacement is necessary. In some cases, repair may suffice.

General Agglomeration Equipment Replacement Considerations

The following factors should be taken into consideration when looking to replace agglomeration equipment of any type:

Failure Analysis

When replacing a unit that has failed, consider conducting a failure analysis, especially if failure was abrupt and/or premature. An equipment audit can help to identify the root cause of failure so that any potential issues can be circumvented with the new unit, either through the design, or through adjustments to the processing environment.

Selecting a Vendor

Choosing an appropriate agglomeration equipment manufacturer requires careful consideration of several aspects, including testing capabilities, the ability to customize equipment, as well as expertise and proven design.

Even if the original equipment manufacturer of the existing unit is still in business, it’s a good idea to explore alternative options that could offer added value.

Data Required

The data necessary to design replacement agglomeration equipment varies based on the specific process and material goals, but several criteria are generally always considered:

Raw Material Characteristics

- Chemical composition

- Moisture content

- Particle size distribution

- Bulk density

- Foreign matter content

- Nature of feed

Desired End Product Characteristics

- Bulk density

- Particle size distribution

- Crush strength

- Moisture content

Process Parameters

- Desired capacity

- Existing processing operation

During this time, it’s also important to look at the original design criteria and consider what has changed in the process since the existing unit was built; has the feedstock changed at all? Has capacity increased or decreased? Have the end product goals changed in response to market demand? All of these factors should be considered in the design of a replacement unit.

Is the material of construction suitable?

It is also a good time to reflect on the suitability of the materials of construction. The chosen materials of construction have a significant impact on the longevity of the equipment and the amount of maintenance and cleaning required.

Carbon steel is a standard material chosen for many types of agglomeration equipment, but some applications may call for a more robust material, or something that is better suited to the specific material characteristics. This might include switching to stainless steel or other alloys. Depending on the equipment, a liner may also be desirable to add another layer of protection.

In the case of rotary drum equipment such as agglomerators or conditioning drums, in addition to upgrading the material of construction, opting for a higher shell thickness or even a rubber lining system provide further options for working with especially abrasive or corrosive materials.

How could the existing design be improved upon?

Replacement also provides the opportunity to improve on the existing design for a more seamless processing solution.

Consider what challenges the existing design presents and how those issues could be mitigated. Do operators continually struggle with the unit for some reason? Is the unit hard to clean? Would a variable frequency drive (VFD) give operators the control they’re looking for? Could the spray system be optimized for better liquid distribution? The potential for improvement is nearly endless.

Spatial Constraints & Accommodations

It’s also important to examine the logistical challenges that may come up during replacement, as replacement of process equipment is often complicated by surrounding infrastructure and may require removal of other equipment or modifications to the surrounding area. Assess the space and determine the best route for the smoothest replacement possible.

Equipment-Specific Considerations

While the information above holds true of all agglomeration equipment, the following looks at considerations specific to the different types of commonly used agglomeration equipment.

Disc Pelletizer in fabrication

Disc Pelletizer (Pan Granulator) Replacement

Questions to consider in replacing a disc pelletizer include:

Is the existing disc size appropriate?

When it comes to the disc pelletizer, consider the disc/pan size. Has capacity changed, or would a larger disc provide more value? Could a smaller disc be used? Some manufacturers may oversize the disc in the original design as a precaution, when really, a smaller disc would be more efficient. For these reasons, it is important to confirm the intended disc size is appropriate for the application.

Would the addition of a reciprocating scraper help?

While standard scrapers are fixed in position, a reciprocating scraper continuously moves across the face of the disc, providing an alternate cleaning method. This is helpful when working with materials that are more likely to stick to the disc, build up on scrapers, or “smear” under scrapers.

Does the entire unit require replacement, or could just the disc itself be replaced?

In some cases, it may be possible to replace only the pan/disc assembly, utilizing the existing drive, base, and other components to minimize replacement costs. This is sometimes the case when working with corrosive materials that have worn the disc, or when abrasive materials have caused excessive wear to the bottom of the disc.

Should I install an enclosure around the disc?

Depending on the material being processed, it may be desirable to install a full or partial hood over the disc. Since the disc pelletizer is an open system, a hood helps to keep fugitive material to a minimum. This is especially beneficial when the material being processed is prone to dust generation, or presents a toxicity risk.

Disc Pelletizer with hood

Pugmill Mixer in fabrication

Pugmill Mixer (Paddle Mixer) Replacement

Specific factors to take into account when replacing a pugmill mixer, also known as a paddle mixer or pug mill, include:

Should a raised cover and spray system be added?

If incorporating a liquid binder or additive into the pugmill mixer, the addition of a raised cover with a spray system can significantly improve binder distribution; by raising the cover and spray system, greater liquid distribution over the tumbling bed can be achieved, promoting a more homogeneous mixture.

Spray system on a pugmill mixer

Would different paddle facings provide a longer paddle life?

Pugmill mixers are often tasked with especially rigorous processing demands. Minimizing wear on paddles is achieved through the selection of a proper facing. Many different types of paddle facings are available, including Ni-hard facings, ceramic liners, tungsten carbide, and more.

Would a pin mixer suit my application better?

In some cases, the pugmill mixer may not be the most suitable mixer for the job and the pin mixer may provide more fitting processing capabilities.

Those looking to explore the use of a pin mixer as an alternative can do so by utilizing a rental pin mixer for in-house testing, or take advantage of testing facilities such as the FEECO Innovation Center, where comprehensive testing programs can be used to evaluate the best equipment for the application.

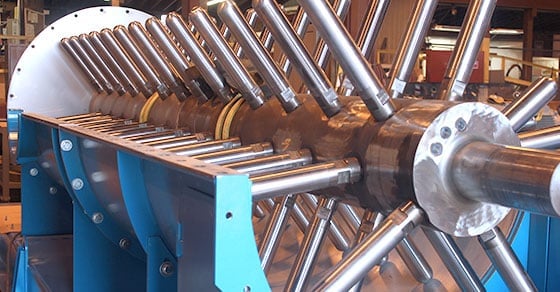

FEECO Pin Mixer (cover removed for photo)

Pin Mixer Replacement

Consider the following questions in replacing a pin mixer:

Would a different cover assembly be beneficial?

Pin mixer covers are available in a few different configurations. The clamshell and self-raising cover designs are an upgrade from standard designs, offering significant time savings for operators and maintenance personnel by mechanising the cover-opening process, mitigating the need for a hoist and any associated risk to employees.

Could a different abrasion-resistant coating on the pins reduce wear?

The intense spinning action that occurs in the pin mixer can cause accelerated wear on pins if not protected with an abrasion-resistant coating. Many different types of coatings such as weld-on coatings or special tips are available, depending on the specifications of the material being processed.

Would a pugmill mixer be a better fit?

Depending on the application, a pugmill mixer may be a more suitable fit. As with the pin mixer, those interested in investigating the capabilities of pugmill mixer with their unique material can do so by utilizing a rental pugmill mixer for in-house testing, or by working with testing facilities such as the FEECO Innovation Center.

Pugmill mixer testing in progress in the FEECO Innovation Center

Coating Drum in fabrication

Coating Drum Replacement

While not a new concept, particle coating is far less established than the broader category of agglomeration, with much to be learned about the mechanisms behind coating. As such, there is often potential for significant improvement when replacing an existing coating drum, as knowledge around this increasingly popular technique has continued to advance. Questions to consider often include:

Could the spray system be optimized?

In almost every case, the answer to this question is a resounding yes. Successful coating is a highly customized endeavor unique to nearly every application, and the spray system is perhaps the most influential aspect of the coating process. Many opportunities for customizing the spray system are possible to improve coating distribution and uniformity. This includes:

- Application rate

- Number of sprays

- Spray method and location(s)

- Nozzle type

Could an adjustment to the coating drum internals improve the process?

In addition to the spray system, the coating drum internals also have a significant impact on the success of the coating process. By incorporating tumbling flights, bed disturbers, or other mechanisms, bed agitation can be improved, promoting a more even distribution of the coating and resulting in a more uniform product.

Coating Drum testing in progress in the FEECO Innovation Center

Could the coating process otherwise be improved upon?

The coating process could potentially be further improved by optimizing several key process parameters, such as material feed rate, retention time, coating temperature, and more.

Coating drum tests can be carried out in the FEECO Innovation Center in order to assess the most effective process and equipment parameters.

FEECO Agglomerator

Agglomeration and Conditioning Drum Replacement

Agglomerators and conditioning drums require many of the same considerations as coating drums, with spray systems and internals playing an important role in the overall success of the unit. One additional consideration to take into account when replacing an agglomeration or conditioning drum is whether or not a liner could improve drum operation and/or product quality:

Could a liner (or alternative liner) improve drum operation and product quality?

Agglomeration and conditioning drums are often fitted with a liner in order to reduce buildup, and in some cases, to protect against corrosion. Liners are available in many different materials and are highly customizable to meeting the intended objective, whether that be to reduce sticking in the unit, or promote greater movement of the material through the drum.

Rotary drum with rubber liner

Conclusion

Whatever agglomeration equipment is in consideration, there are many factors to evaluate during the replacement process. From choosing the appropriate materials of construction, to figuring out the logistics of the actual replacement, and even switching to an alternative technology, those in need of replacement equipment should consider all options in order to meet or exceed their existing unit’s capabilities.

FEECO’s expertise in agglomeration testing, custom equipment, and parts and service support is sought by the world’s most renowned companies. For more information on our agglomeration offerings, contact us today!