In regards to rotary dryer use, retention time is the duration of time that a material must remain in the dryer to achieve the desired end-product characteristics.

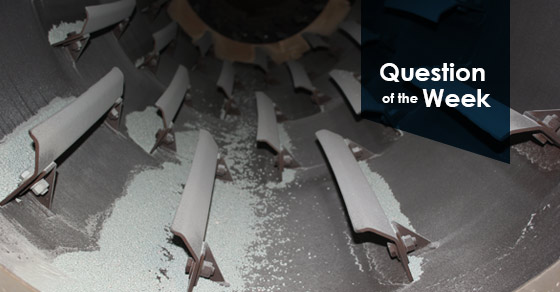

Retention time is an important consideration to the dryer design, and is defined by looking at the specific heat, heat transfer properties, and moisture content of the material. Retention time is also controlled through a combination of factors such as dryer length, slope, and dam plates.

To confirm the ideal retention time, FEECO recommends your material go through a research and development process at our Innovation Center. The information gained through testing allows us to design the most efficient drying system unique to your material requirements.

For more information on rotary dryers, contact us today!