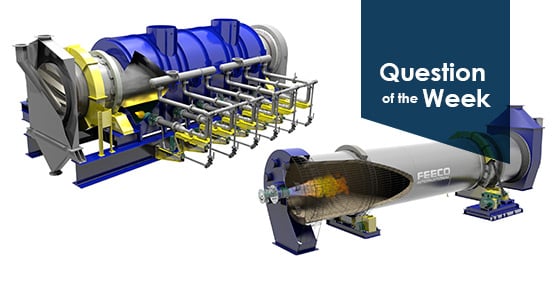

Indirect rotary kilns, or rotary calciners, offer three major advantages over their direct-fired counterparts, as outlined below.

- When processing in a direct-fired rotary kiln, fine materials can become entrained in the gas and carried out to the baghouse. An indirect kiln avoids this issue because there is minimal air moving through the drum.

- Smaller exhaust gas treatment equipment is required because the heating medium is kept separate.

- The processing environment in an indirect kiln can be more tightly controlled. Indirect-fired rotary kilns allow temperatures to be adjusted along the length of the drum, which provides precise temperature control.

FEECO is a leader in custom thermal processing equipment and solutions for both indirect and direct-fired rotary kilns. Our team of process engineers look forward to helping determine the right kiln for your needs. Contact us today, to learn more.