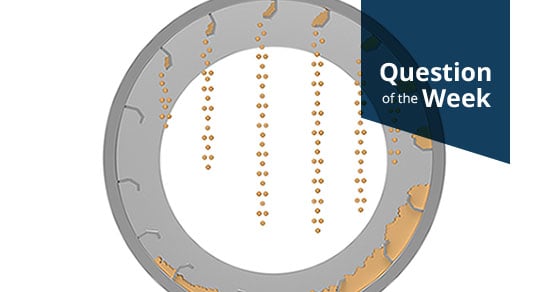

A rotary dryer’s flights, or material lifters, work by lifting the material and dropping it through an air steam. This process creates a curtain, or a shower of material spanning the width of the drum’s interior. The curtain maximizes heat transfer between the material and the process air.

Flights must be designed to work with the unique characteristics of the material to be processed, in order to create the ideal curtain, and overall, most efficient drying process. From stickiness to high angle or repose, no material is alike, and therefore, no flight should necessarily be designed alike either.

Various factors work together to influence how the material will respond in the drum. Such factors include:

- Flight size/shape

- Flight placement inside of the drum

- Flight material of construction

- Drum speed

- Loading

Testing these various factors in a flight simulator allows one to determine the best flight setup for their unique material and processing requirements.

Whether one is looking to determine the ideal flight design or pattern in a rotary dryer, optimize the flights in an existing piece of equipment, or test a change in process conditions, testing with the FEECO flight simulator can help. Results from the flight simulator test can then be used to engineer a custom rotary dryer suited to your process requirements.

Download our [Download not found] to learn more.