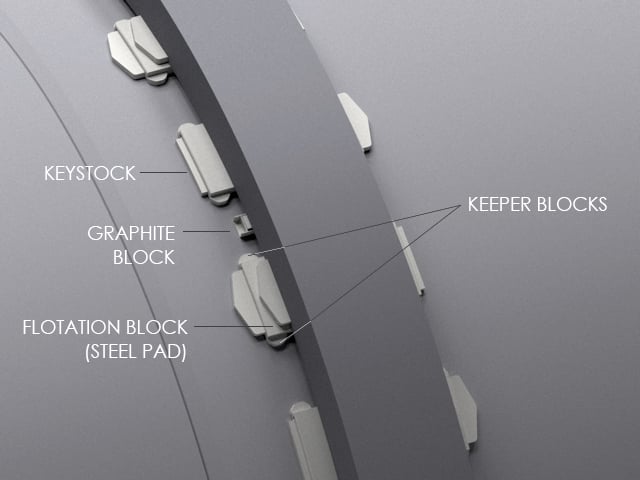

The mounting assembly is the interface between the rotary drum shell and the tire, or riding ring. This interface provides critical support to the drum during rotation. While FEECO utilizes the floating tire mounting assembly pictured below, we can assist in the assessment and maintenance of all types of mounting assemblies, including wedged and shrink-fit.

3D Diagram illustrating the floating tire mounting assembly and its components

Reshimming

As the tire and mounting components experience normal wear and tear, flotation blocks/filler bars become worn or compressed, leaving a gap and subsequent lack of support between the filler bar and tire bore. In addition to creating an imbalance in tire/drum shell support, this gap also allows for the tire to migrate around the drum at an accelerated rate (tire creep). Tire creep works against the drum’s thrust forces, wearing away keeper blocks and if left unchecked, escalating to axial movement of the tire.

Reshimming, which involves placing metal shims beneath filler bars, is conducted to restore the proper tire-to-shell interface and provide adequate support.

The frequency of reshimming depends on the drum’s unique wear conditions, but is generally required every 3-7 years. When done early and correctly, the reshimming procedure can extend the life of the tire and avoid more intensive repairs.

What are the Signs that Tire Reshimming is needed?

The need for reshimming is indicated by excessive tire creep, a measurement that plant maintenance personnel and reliability engineers should regularly monitor.

When creep on an operating/hot drum reaches 1/2” per revolution, FEECO recommends ordering a shim kit to have on hand. When creep reaches 3/4”, a remount should be planned for the next available outage.

Remounting & Upgrading

When reshimming is no longer sufficient, typically after two reshims have been performed, the tire must be remounted. This process, which typically occurs around 10-15 years after installation, entails the complete replacement of all mounting hardware, cleaning and repair of the underlying drum shell (if needed), and repositioning and alignment of the tire.

What are the signs that remounting or upgrading are needed?

Indications that a remount is necessary may include:

- Tire creep or migration beyond float limits

- Presence of axial runout

- Running (hot) gap is too big to keep shims in place

- Wear on side keepers

- Visible scoring, pitting, or wear on the tire bore or shell

- Excessively worn flotation blocks

- Floating block riding on top of the small keepers, due to a large gap

Rotary drums utilizing an outdated mounting style should be upgraded to the floating tire mount, which offers improved performance and longevity for all components and reduces the high maintenance requirements and safety risks associated with hardware failure in older-style mounting systems.

Replacement

Tire service life is highly dependent on operating conditions, but is generally 25+ years. However, once the tire experiences damage, cracks, severe wear, or is less than 90% of its original thickness, tire replacement and and a new mounting assembly are required. Due to the lead time on tires, replacement must be planned well in advance.

Can Tire Cracks Be Repaired?

Cracks in the tire can be temporarily fixed through highly skilled welding repair with eutectic materials, but will eventually require replacement.