Rotary dryers and kilns are an integral part of the many industrial processes that shape our world. From fertilizer and chemical production, to ore beneficiation and even consumer products, these rotary drums provide a reliable, high-capacity setting for accomplishing a number of necessary objectives when it comes to processing bulk solids.

The efficiency of a rotary drum, no matter what its purpose, is often key to maintaining a steady workflow and upholding quality standards. One factor that can have a significant impact on the overall performance of the unit is the rotary drum seal.

Rotary Drum Seals: A Necessity for Efficiency

Seals bridge the gap between the rotating drum and the stationary housing to provide a sealed processing environment within the drum while still allowing the drum to rotate smoothly.

Seals help to ensure that the rotary drum and overall process perform as intended. This is less of a concern when working with agglomeration and granulation drums (these drums typically use a very simple seal called the Labyrinth seal), and more of a concern when working with drums that utilize heat transfer and a controlled processing environment. Seals are used to stop air leakage into the rotary drum, which can cause the internal temperature to deviate and the process to decrease in efficiency, sometimes significantly. This often results in increased fuel consumption and residence times, inferior product, or even a reduction in throughput.

Seals are especially crucial when working with rotary kilns, where high temperatures are employed and the atmosphere inside the kiln must be tightly controlled. Rotary kilns use this controlled environment to cause a chemical reaction or phase change within the material being processed. Air leaking into the system has the potential to change processing conditions, therefore disrupting (or not allowing) the intended reaction. Again, this could result in lost or inferior product, or the need to reprocess the material.

Because of the high temperatures they employ, most rotary kilns are run at a negative pressure in order to prevent the heat and combustion gases from leaking out. However, air can leak in as a result of this negative pressure, potentially causing the temperature to drop. Similarly, many kilns may require a specifically designed atmosphere within the kiln, such as an inert (low- or no-oxygen) atmosphere. In either case, seals are used to prevent the exchange between the internal and external kiln environment, allowing the processing to occur efficiently and as intended.

Seal Options

Seals are available in a variety of designs. FEECO offers three primary seal types for our rotary equipment, with selection and customization based on factors such as the needs of the material being processed, emission gases, internal gases, and more.

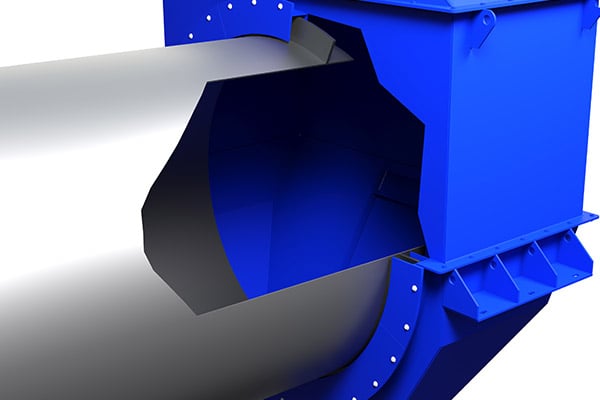

3D Model of a Labyrinth Seal

The Labyrinth Seal

When air leakage is not a major concern, such as with agglomeration or granulation drums, the labyrinth seal is a common choice. The labyrinth seal is a cost-effective option with a relative leakage of >> 5.0%. This seal provides a torturous path for the ambient air by means of close clearance between the rotating seal ring and the stationary housing. With this seal, flexible wrap can also be added between the seal plate and rotating shell, in order to improve the seal.

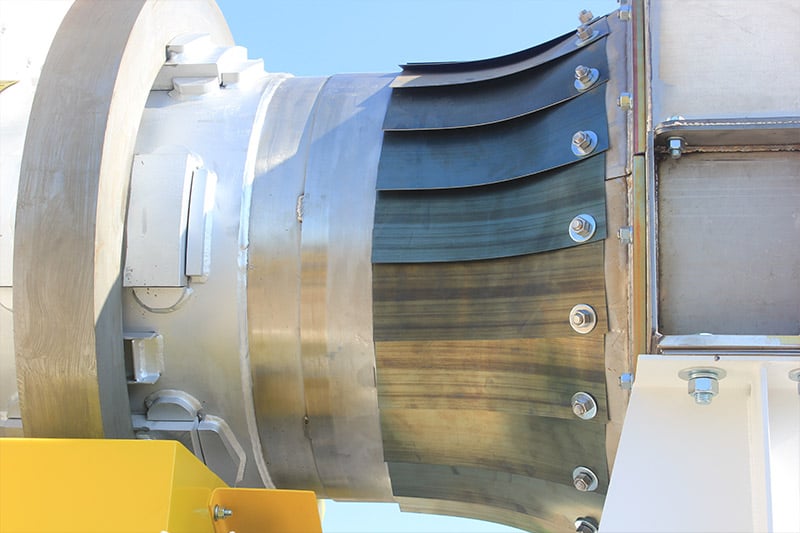

Single and Double Leaf Seals

The single leaf seal offers a bit more sealing power, with a relative leakage of << 3.0% to 5.0%. This seal consists of a series of overlapping spring plates. Similar to a fanned out deck of cards, the leaves, or “cards,” are made out of spring steel, and are forced to push against the wear plate of the rotary drum. These fanned leaves naturally keep pressure on the rotating drum, keeping a good seal.

The double leaf seal is a variation of the single leaf seal, but offers increased sealing ability with a relative leakage of <<1.0% to 3.0%. As such, the double leaf seal is used when less leakage can be tolerated than with that of a single leaf seal. The double leaf seal is similar to the single leaf seal, but consists of two single leaf seals with a ceramic fiber blanket between the two layers of leaves.

Image: A single leaf seal connects this rotary drum to the discharge breeching.

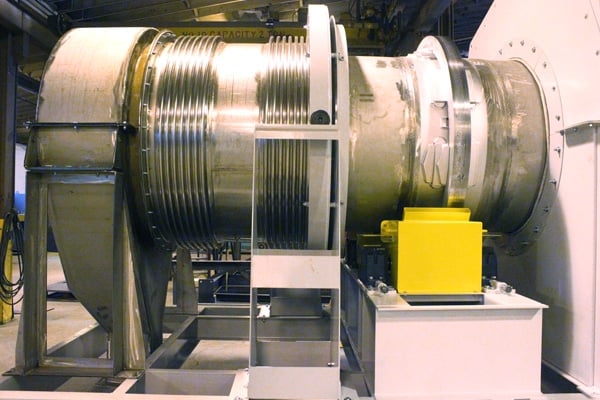

The Bellows Seal

The bellows seal has a relative leakage of << 1.0%. The advantage to this seal type is that it can accommodate significant longitudinal expansion, which is ideal in higher temperature operations.

A wear material such as graphite or bronze wear ring with grease is used as a face seal, compressed against the rotating surface to provide a seal.

Image: A bellows seal connects this rotary drum to the discharge breeching.

Signs that a Seal is Not Functioning Properly

While seals are always provided as part of a rotary drum purchase, existing operations may benefit from replacing old or ineffective seals. Determining whether a seal is, or will soon be, in need of replacement is often as simple as a visual inspection. Examining the seal on a weekly basis can help to indicate that a seal is wearing and may soon require repair or replacement. Signs that a seal is in need of attention include:

- Visible wear on seals, such as missing or worn seal leaves

- Abnormal auditory cues such as chattering or vibration

In addition to these indicators, unexplained process inefficiencies may also be a sign that a seal is not performing as intended.

Conclusion

Seals are an integral component in the overall performance of a rotary drum, particularly when controlled heat transfer is being utilized. The selection of the proper seal for a given application promotes optimum processing efficiency, a clean and safe work environment, and allows the process to be carried out as designed. Replacing inferior seals can help to get a process back to efficient operation.

FEECO is an expert in custom rotary drums, from granulators and coating drums, to dryers, coolers, and kilns. For more information on how we can assist your rotary drum operation, contact us today!