Rotary kilns are used in a variety of thermal processing applications, and depending on the material being processed and the process objectives, internal components are often employed to improve efficiency. One such component is the bed disturber, widely employed in indirect kilns.

While not always necessary, bed disturbers can play a key role in optimizing kiln performance—especially in situations where heat transfer is lacking, or a process is under-performing. In some cases, they are added to existing kilns as a retrofit to correct issues such as poor bed movement, material buildup, or inconsistent product quality.

The Function of a Bed Disturber

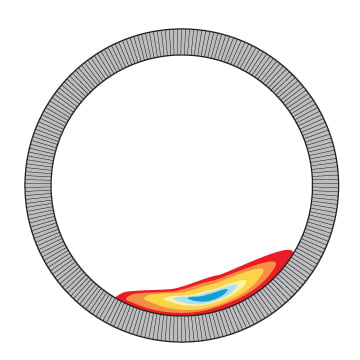

In indirect-fired kilns, where heat is transferred through the shell wall rather than by direct contact with the flame or combustion gases, proper material bed movement is essential. Ideally, the material bed should roll, exposing fresh material to the hot kiln shell. However, without sufficient agitation, the bed may slide instead—limiting heat transfer and resulting in uneven exposure.

In a bed that just slips along the interior of the rotary kiln, the inner part of the bed never really gets exposed to the rotary kiln shell, creating major temperature discrepancies.

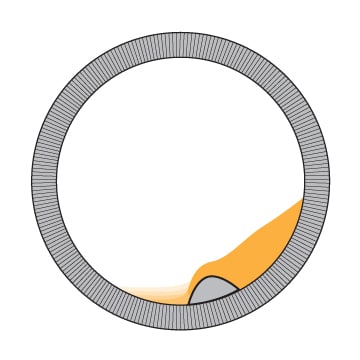

Bed disturbers are internal features designed to improve the tumbling action of the material bed. By promoting better agitation, they ensure that the material is consistently and uniformly exposed to heat. This leads to more efficient processing, higher-quality product, and better use of energy input.

Fixed to the interior of the rotary kiln, a bed disturber turns over the bed of material by creating a place for the material to build up and tumble over, redistributing what was on top to the bottom, and vice versa.

What Happens Without Bed Disturbers?

In indirect-fired kilns that lack adequate bed agitation, sliding of the bed along the interior wall is common. This can lead to:

- Cold zones where heat transfer is insufficient

- Overprocessing in some areas and underprocessing in others

- Material buildup, especially with sticky or high-residue materials

- Extended retention times, reducing throughput and energy efficiency

Bed disturbers solve this by creating additional mechanical interaction between the rotating shell and the material bed, forcing a rolling action that continually exposes fresh material to the hot shell wall.

Common Bed Disturber Designs

The type of bed disturber, along with its design, is tailored to the unique process and material requirements, but is generally based on one of two types:

Bar Bed Disturber

This design involves a metal bar that runs longitudinally along the interior of the kiln. As the kiln rotates, material encounters the bar, which disrupts its motion and encourages material to roll over, redistributing the bed. This simple design is effective in uniform-temperature kilns but can be prone to warping or thermal stress in high-heat zones if not properly designed or constructed from heat-resistant materials.

Flights (Lifters)

Flights—angled plates mounted at intervals inside the kiln shell—offer an alternative approach to bar bed disturbers. While in rotary dryers, flights are designed to scoop and lift the material as the drum rotates, creating a cascading effect that enhances agitation and heat exposure, flights intended for bed turnover work a bit differently.

Rotary dryer flights tend to employ single- or double-bend flights to facilitate the scooping action. In indirect rotary kilns or dryers where a cascading effect would offer no additional benefit due to the lack of combustion gases inside the drum, flights tend to be more simple. Here, flights may consist of straight plates or small metal blocks installed at an angle inside the drum’s interior. In both cases the flights provide just enough agitation to ensure uniform heating.

While incorporating flights is more complex than a single bar bed disturber, flights offer better performance in kilns with variable temperature profiles, as their design can better accommodate thermal expansion and temperature gradations along the length of the kiln.

Rotary kiln interior with bed disturber flights

Design Comparison

| Feature | Bar Bed Disturber | Flights |

| Best for | Uniform temperature zones | Variable temperature zones |

| Mixing Efficiency | Moderate | High |

| Thermal Resilience | May warp under high heat | Accommodates thermal expansion |

| Risk of Build-up | Moderate | Lower due to better agitation |

| Maintenance Requirements | Low to moderate | Moderate (depending on wear) |

| Installation | Simple, welded or bolted bar | Welded or bolted plates |

When Bed Disturbers Are Needed

While not every kiln requires a bed disturber, certain operational symptoms may signal the need for one:

- Material bed sliding instead of rolling

- Cold spots within the bed

- Uneven product quality

- Reduced throughput or long retention times

- Material buildup on the kiln wall

In these cases, adding a bed disturber can dramatically improve kiln performance by encouraging consistent bed motion and uniform thermal exposure.

Retrofitting Bed Disturbers

When a kiln is underperforming but still structurally sound, retrofitting bed disturbers can be an efficient and cost-effective solution.

Important considerations in evaluating such a retrofit include:

- Material behavior: Sticky, friable, or thermally sensitive materials may benefit more from specific types of bed agitation.

- Kiln temperature profile: Thermal gradients may require a flight-style approach over a bar bed disturber.

- Accessibility: Bed disturbers may be welded or bolted into place, depending on ease of access and maintenance preferences.

- ROI: Improved product uniformity and shorter cycle times typically offer a strong ROI.

Testing in the FEECO Innovation Center

Choosing the right bed disturber design depends on a variety of factors, including material characteristics, process goals, and kiln conditions. To help customers make informed decisions, FEECO offers process development and testing services in our Innovation Center, where real-world conditions can be simulated at pilot scale.

A key tool in this testing is our flight simulator, which allows engineers to trial different internal configurations—including bed disturbers such as bars and flights—and observe how they impact material bed behavior and heat transfer. This hands-on approach ensures that the selected design performs as intended before committing to full-scale production or retrofit.

Through trials, FEECO can:

- Evaluate material flow and bed movement

- Test heat transfer efficiency with different disturber styles

- Optimize retention time and mixing

- Reduce the risk of costly rework or performance issues in the field

This testing capability is especially valuable when working with unique or sensitive materials that may behave unpredictably in a full-scale kiln environment.

Bed disturber test in progress using the FEECO flight simulator

Conclusion

Bed disturbers are a simple yet effective tool for enhancing indirect rotary kiln performance, especially in processes with limited material mobility. By improving the rolling action of the bed, they enhance heat transfer, improve product uniformity, and can help resolve operational challenges like cold spots and inconsistent processing.

Whether integrated into a new kiln design or added as a retrofit, bed disturbers provide a low-cost way to extract more performance from a thermal processing system.

With decades of experience in custom rotary kiln design and thermal processing, FEECO International helps customers evaluate the need for bed disturbers through testing and process audits. We also offer parts and service support for maintaining bed disturbers and other kiln internals. For more information on our rotary kiln capabilities, contact us today!