Copper concentrate dryers play a crucial role in preparing feedstock for smelting—one of the primary methods of producing copper and a key contributor to meeting the growing demand for the red metal in the shift to a low-carbon economy.

Although several smelting technologies are available, all rely on dry feed material to optimize efficiency.

Rotary dryers, widely used across the mining and mineral processing sector, are among the most trusted solutions for drying copper concentrates in support of this goal.

Benefits of a Dry Feed to the Smelter

Copper producers gain several cost-saving advantages by employing a dryer for copper concentrates prior to the smelter.

By the time they are ready to be smelted, copper concentrates typically contain anywhere between 6-14% water. The different smelting technologies have varying requirements for moisture content. Typically this ranges from 0.2% to 10%, with modern flash smelters – an increasingly used type – having the lowest tolerance for moisture.

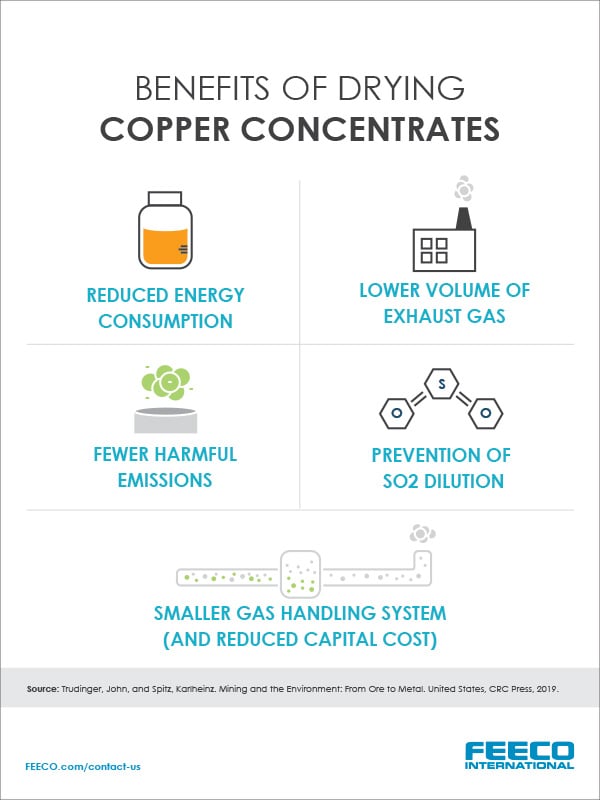

The benefits gained by drying copper concentrates prior to the smelter include:¹

- Reduced energy consumption

- Lower volume of exhaust gas

- Fewer harmful emissions

- Prevention of SO2 dilution

- Smaller gas handling system (and subsequently reduced capital cost)

By drying copper concentrates, producers can ultimately reduce costs associated with fuel and exhaust gas handling, as well as have a more concentrated stream of SO2 , which is then less costly to convert to sulfuric acid.

For many, these benefits are in addition to the efficiencies and cost savings already gained by implementing a mixer for copper concentrates.

Rotary Dryers for Copper Concentrates

Rotary dryers offer an excellent industrial drying solution for copper smelters looking to reap the benefits of drying. Their heavy-duty construction and high-capacity throughput are ideal for copper processing settings.

Additionally, the diverse opportunities for customizing the rotary dryer against the harsh nature of copper concentrates enables producers to further protect their investment through smart design.

Conclusion

Drying is a critical part of the smelting process, particularly as flash smelters continue to gain market share as a preferred approach to smelting. Rotary dryers, with their robust construction, high capacity, and potential for customization, are an ideal fit for copper smelting operations.

FEECO has been building custom rotary dryers for the mining industry since 1951. We offer feasibility and pilot-scale testing options in our Innovation Center for gathering the process data needed for scale-up, as well as a comprehensive parts and service program. For more information on our rotary dryers and related services, contact us today!