As several factors contribute to increased animal protein demand, phosphate feed supplements are playing an increasingly important role in meeting animal nutrition and global food security needs. A recent market report predicted that the phosphate feed market will grow at a CAGR of 4% to 2029, landing on a valuation of USD 3.43 billion, up from USD 2.82 billion in 2024.

About Phosphate Feed Supplements

Phosphorus is a primary nutrient of life, essential to overall animal health and productivity; the nutrient plays a key role in metabolism, reproduction, and many other physiological functions.

Unfortunately, organic sources of phosphorus cannot meet the necessary requirement for optimal growth and wellness, due to a low digestibility. A deficiency in phosphorus can cause a number of health issues, all of which lead to reduced productivity. Issues often include stunted growth, lack of appetite, inadequate bone formation, lower milk quality, and more.

As such, phosphorus must be supplemented through the inclusion of inorganic feed phosphates. Products such as monocalcium phosphate (MCP), dicalcium phosphate (DCP), and tricalcium phosphate (TCP) are subsequently vital to maximizing animal health and productivity, and ultimately, securing the world’s available supply of animal proteins as the growing population demands more meat and animal products than ever before.

Factors Pushing Demand for Feed Phosphates

The increasing demand for phosphate feed additives is directly related to the growing demand for high-quality animal protein being seen across the globe.

Meat production is incredibly phosphorus intensive; a 2012 study recognized meat consumption as being responsible for 72% of the phosphorus footprint. The study investigated the impact of various diets on phosphorus demand and found that between 1961 and 2007, the global phosphorus footprint per capita increased 38%.¹

Several factors are driving demand for more animal proteins:

Developing Nations

As developing countries continue to advance and their disposable incomes rise, societies are increasingly incorporating more meat into their diets. In addition to a greater quantity of meat, demand for more diversity in meat products also expands with development, prompting a need for a widespread increase in protein production of all types.

Growing Global Population

In addition to developing countries requiring more meat, the burgeoning global population is also putting a strain on food resources, demanding more food than ever before. Between 2008 and 2017, global meat consumption rose 2% annually. Experts anticipate that this will continue in the coming years, but growth will be localized, owing to dietary preferences and trends, urbanization, and developing nations.²

Urbanization

Demand for animal proteins and livestock products also increases with urbanization; city residents consume both a greater quantity of meat, as well as a more diversified range of meats. More than half of the world’s population currently resides in an urban area, with the trend toward increasing urbanization expected to continue.

An Evolving Industry

In addition to the phosphate feed industry growing, it is evolving as well, with a number of changes taking place.

The Switch to MCP

Livestock and poultry producers are increasingly choosing MCP over DCP. Not only does MCP have a higher phosphate content and offer a highly soluble source of phosphorus, but it is also more digestible, improving feed efficiency and reducing the potential for nutrient runoff.

Premium Products Preferred

The industry is increasingly turning toward the use of premium products in order to maximize efficiency. More than ever, producers are relying on granular products over ground/powdered products, as they offer many advantages, including improved palatability, reduced dust and product loss, greater flowability, and more.

Depending on the method of production used, granulation can be incorporated into the production process itself, or as a post-production step in a granulation drum or other pelletizing (wet granulation) device.

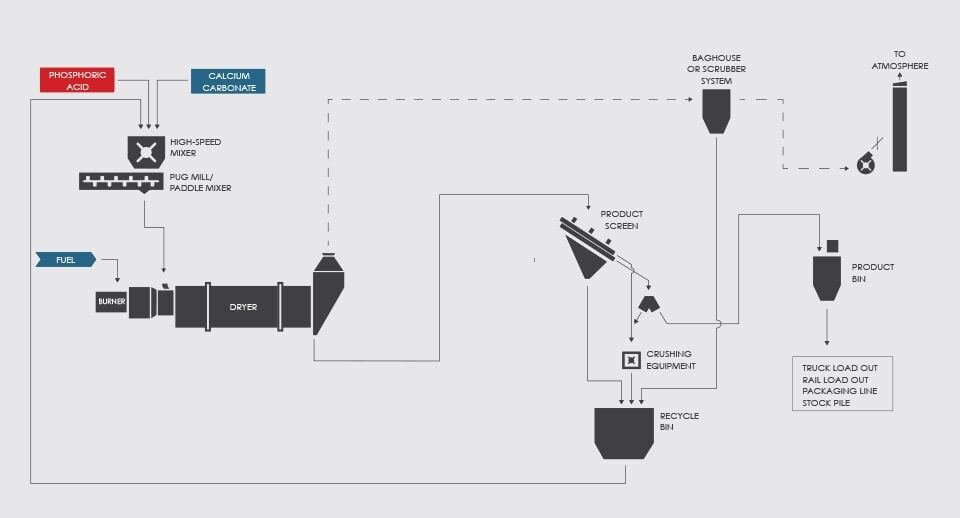

FEECO has improved upon the traditional approach to phosphate feed granulation through the incorporation of a more complete reaction of the feed materials. Here’s how it works:

Mined phosphate rock is processed to liberate phosphate from the gangue. The beneficiated ore is then processed in a phosphate rock dryer to reduce the moisture content, and if contaminated, a rotary kiln to remove any organic components.

The resulting phosphate is then reacted with sulfuric acid to produce phosphoric acid, which is in turn reacted with calcium carbonate (limestone) to yield the desired feed-grade phosphate product.

The limestone and phosphoric acid reaction has historically been carried out through the use of a pugmill mixer type of reactor. Through extensive engineering, FEECO developed a vertical high-speed mixer specifically to complement the pugmill in this process.

The high-speed mixer is mounted atop the pugmill. Running at 300-400 RPMs, the intense mixing action created by the high-speed mixer more uniformly combines the feedstock components, producing a homogeneous mixture. This jumpstarts the reaction process, which finishes as the material drops into the pugmill mixer and is granulated as a result of the kneading and folding motion promoted by the twin shafts fitted with paddles.

The result is a premium animal feed product exhibiting a high level of uniformity. The process concludes with drying, screening, and a recycle circuit as usual.

FEECO High-Speed Mixer prepared for shipment

The high-speed mixer can be seen mounted atop a pugmill mixer

This simplified flow diagram illustrates the FEECO approach to phosphate feed granulation incorporating a high-speed mixer before the pugmill mixer.

Conclusion

As developing nations, increasing urbanization, and an expanding population demand more high-quality animal proteins than ever before, animal protein production will increasingly depend on phosphate feed supplements such as MCP, DCP, and TCP.

FEECO provides the industry with the most reputable phosphate feed production equipment available, including pugmill mixers, rotary dryers, and our exclusive high-speed mixer for improved feed product quality. We also offer a testing facility for assisting in R&D activities, as well as a comprehensive parts and service team skilled in inspecting, repairing, and replacing production equipment in the animal feed granulation line. For more information on animal feed production equipment, testing services, or parts and service support, contact us today!