FEECO manufactures two bucket elevator designs: centrifugal and continuous. They are built to move bulk materials vertically, and offer their own distinct advantages to the bulk handling operation at hand.

Continuous bucket elevators are used for less vigorous bulk material handling applications. The slow speed of this elevator type avoids the throwing action associated with centrifugal style elevators. Continuous elevators are then ideal for fragile materials, or materials that are prone to aeration.

Here’s how they work: material is fed into the buckets from an inlet chute. Material then gently pours out of the bucket and slides down the inverted bucket and into the discharge chute.

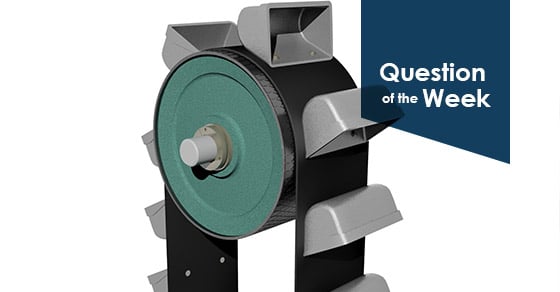

Centrifugal bucket elevators are ideal when large amounts of material need to be moved quickly. They are often selected for handling durable and abrasive materials such as gravel, woodchips and sand.

Here’s how they work: Buckets scoop material up from the boot or inlet sections. Centrifugal force at the head pulley “throws” material from the buckets and into the discharge chute.

For more information on bucket elevators, download our brochure, or contact us today!