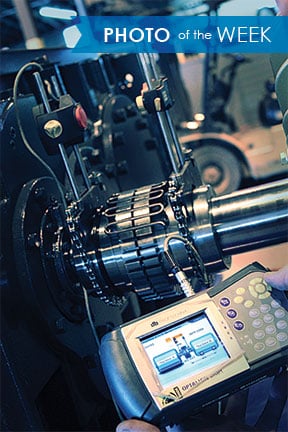

This week’s photo, taken in the FEECO Fabrication facility, shows a FEECO employee using a laser shaft alignment tool to properly align the coupling on the shafts of a drive assembly.

The coupling joins the shafts between the drive motor and reducer. The shafts are aligned within a tight tolerance ( typically less than 0.010” in parallel and angular alignment) to keep the gear box, as well as the rotary drum, whether a rotary dryer, cooler, or kiln, running smoothly. Proper alignment is extremely important to reduce maintenance, increase drive component life, and ultimately avoid down time and costs accrued through damage.

As can be seen in the photo, the computerized tool is attached to the coupling hubs, the shafts are rotated, and the tool takes readings of the tolerances. It then instructs the operator how to adjust the position of the motor to get within the required tolerance.

This is just another way FEECO brings their customers a quality product. For more information on rotary drum maintenance, or FEECO’s capabilities, contact us today!