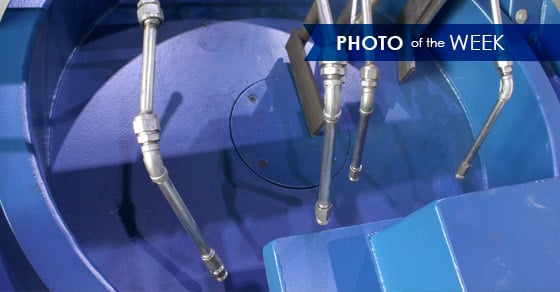

This week’s photo highlights a pan pelletizer’s binder spray system.

The spray system, or nozzles, are used to disperse binder. Non-pressure agglomeration technologies, such as pelletizing on a pan pelletizer (also known as a pan granulator or disc pelletizer), often requires the assistance of a binding agent to achieve agglomeration.

When material is fed onto the pan pelletizer at a continuous rate, binder is also continually added. The material fines become tacky as a result of the binder addition, and as they tumble among themselves while the pan rotates, they pick up more fines and grow in size. When the pellets reach their desired size, they exit the pan and are transported to a rotary dryer if moisture removal is necessary.

The location of the nozzles, binder feed rate, and binder formulation all play an influential role in achieving the pellets you are looking for. For more information, contact us today!