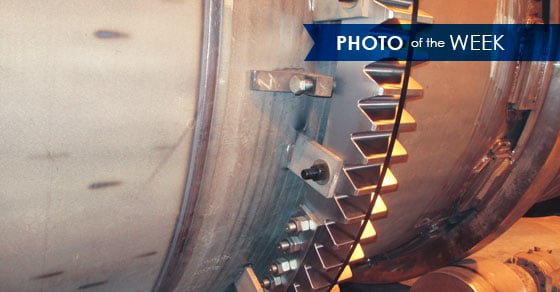

This week’s photo highlights a girth gear run-out procedure in action.

A black strap (pictured) is mounted along the gear’s teeth. A dial indicator follows the strap’s path, and measures the tip of the teeth along the strap. This procedure reveals the amount of wear on the gear.

Generally speaking, a girth gear that does not meet ideal measurements should be replaced, or other areas of the drum can be negatively affected. Replacing, as opposed to servicing the gear, is often the most economical choice.

Girth gear run-out procedures should be done on newly installed drums, and during annual inspections. FEECO’s Customer Service Engineering team can travel directly to your facility and perform the gear inspections, and they can also quote replacement gears.

To learn more, contact us today!