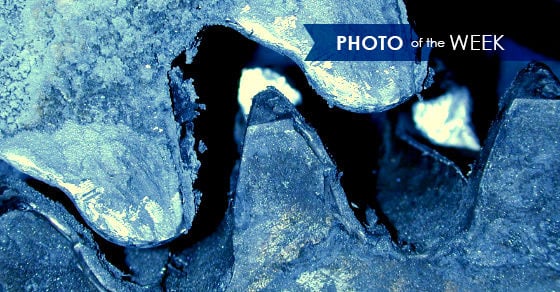

Today’s photo shows the gear mesh of a gear and pinion drive, the mechanism that causes a rotary drum to rotate.

The face of the teeth here are worn, an indication that the gear should be replaced, or they may break off. In most cases, replacement is ideal. There are times, however, that flipping the gear is a possible solution, though it is still weak and susceptible to breakage.

Telltale signs that indicate the need for gear replacement include: unusual vibrations coming from the drive, growling noises, and even wear patterns on the tires.

FEECO’s Customer Service Engineers often conduct equipment audits to diagnose worn parts, such as the gear mesh shown. Our team can advise when repairs or parts replacement is necessary, and they can even amend the issues themselves. Regular inspection and timely maintenance is key to rotary drum longevity.

If your rotary drum is in need of an inspection, maintenance, or spare parts replacement, contact a FEECO expert today.