Rotary kiln air flow configuration is an important consideration in kiln design. Counter current and co-current are the different types of air flow options available, each offering distinct advantages and disadvantages.

In co-current air flow configuration, the material and process gas flow in the same direction. This process places the coldest material in contact with the hottest gas, and results in a quick temperature change. Co-current air flow is ideal for materials that do not require a gradual temperature change for a controlled transformation. An example includes organic combustion processes because they typically do not require a specific end product.

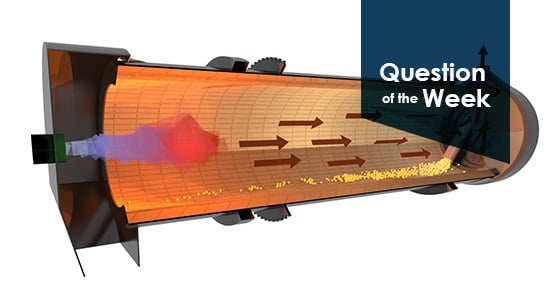

In a counter current air flow configuration, the material and process gas move in opposite directions. This allows the material to be gradually heated as it flows through the rotary kiln. Here, material comes into contact with the hottest process gas before discharge, and proves to be advantageous in regards to the thermal efficiency it provides. The counter current design is also commonly used when a more controlled physical or chemical change is required. Finally, the counter-current configuration is more common that its co-current counterpart.

For more information, download our rotary kiln e-book, or contact us today!