While a number of disposal and treatment methods for managing biosolids exist, the opportunity to reuse biosolids as a value-added product offers a sustainable approach to waste management.

The following covers some of the current and trending methods used to dispose of biosolids, as well as the opportunities available for reuse and recovery.

Approaches to Biosolids Disposal

Landfill

While a modern landfill is a safe and reliable approach to disposing of waste solids, there are a number of downsides with this method.

Perhaps the most critical issue is that landfilling waste solids disregards the valuable nutrients and organic matter that the collected sludge holds, ultimately wasting a potentially valuable material. Many of the nutrients that are thrown away in the landfill with the biosolids are non-renewable, requiring fossil fuel inputs to produce more. The ability to put these nutrients back into the ecosystem would not only be a more sustainable alternative to producing more, but would also avoid the material taking up space in a landfill.

In addition, hauling wet solids to the landfill can be a costly endeavor. Utilizing the waste material as a value-added product would provide a revenue stream where waste disposal costs were previously incurred.

Incineration

Wastewater treatment sludge can also be disposed of through combustion in an incinerator. Incineration is a particularly viable approach where available land for application is limited.

This capital-intensive approach reduces the biosolids to a small amount of ash, which is then typically sent to a landfill. While the ash may have a very high nutrient value, the metals also tend to concentrate in the ash, limiting its marketability. While FEECO has supplied ash granulation systems to add value to this waste stream and produce a granular ash product, air quality and permitting issues associated with incineration have made this approach less common, and this trend is expected to continue.

Composting

Composting is a treatment approach that offers low capital and operating costs for processing. The land requirement to properly windrow is significant, however, as the required retention time is typically around 6 weeks.

The major disadvantage to this approach is that the product is typically of little resale value, usually around $10 – $20 per ton. Despite being a wonderful soil amendment, rich in organic matter and micronutrients, the compost is in a physical form that cannot be readily incorporated into existing product lines and is difficult to transport, ultimately limiting its marketability. There is a solution to this problem, however: organic waste granulation, or organics granulation. Organics granulation transforms a material that is difficult to handle into an easy to use, dry granular product that can be easily incorporated into existing product lines.

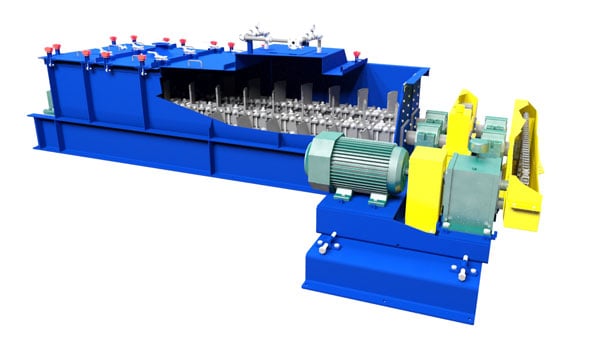

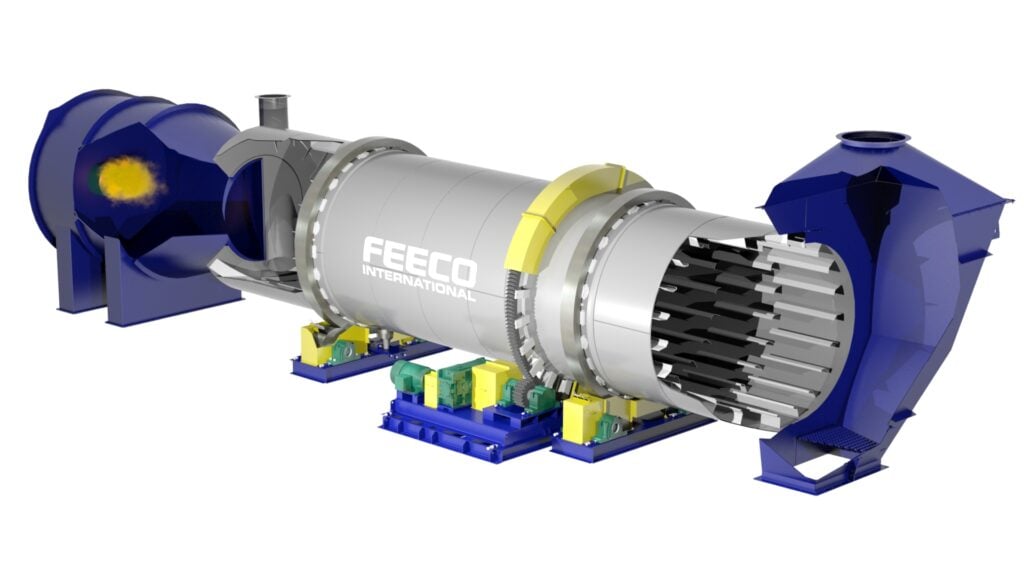

The key pieces of equipment required for organics granulation are a FEECO Paddle Mixer and Rotary Dryer, shown below. Once granulated and sized to meet fertilizer standards, the compost can be handled and spread with standard equipment. The compost can also be bulk blended with chemical fertilizers, greatly increasing its marketability and value.

Drying and Granulation

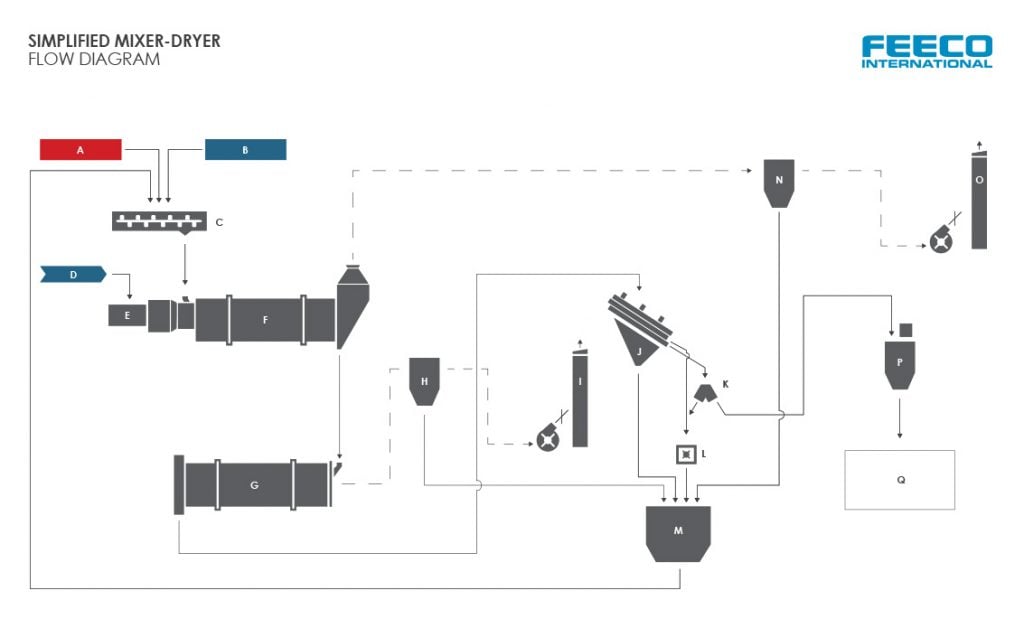

For most sewerage districts, the ideal solution for wastewater sludge processing is the production of high-value fertilizer granules. Similar to the granular compost approach, a granulation facility produces a high quality fertilizer granule from the sludge. A simplified process flow diagram is shown below.

The image below shows a simplified organics granulation system with a mixer-dryer setup.

| Flow Diagram Key | |

| A – Raw Feed B – Binder C – Paddle Mixer D – Fuel E – Burner F – Rotary Drum Dryer G – Rotary Cooler H – Baghouse I – Stack (to Atmosphere) | J – Product Screen K – Product Diverter L – Crushing Equipment M – Recycle Bin N – Baghouse O – Stack (to Atmosphere) P – Product Bin Q – Load Out, Packaging Line, Stock Pile |