In thermal processing applications, controlling moisture content is critical to achieving both material quality and process efficiency. A common challenge in designing rotary kilns for bulk solids is determining whether the unit can—or should—be used to remove excess moisture from the feedstock.

While rotary kilns are capable of driving off moisture, they are not always the most efficient or appropriate solution. This article explores the role of moisture in rotary kiln design and operation, offering guidance on when a kiln is suitable for drying—and when a rotary dryer or other industrial drying system may be more effective.

Moisture Types: Free vs. Bound Moisture

An important distinction in evaluating a thermal process is the type of moisture present in the material—specifically, free vs. bound moisture.

Free Moisture

Free moisture refers to water that is loosely held on the surface of particles or in a material’s pore spaces. It evaporates readily and typically requires lower temperatures to remove. Most feedstock materials carry some level of free moisture. For example, surface moisture is easily evaporated from limestone pellets after pelletizing via wet granulation.

Rotary dryers, operating at temperatures between 800º – 1400ºF and promoting a high rate of heat transfer, are extremely effective at removing free moisture to reach a target moisture content.

Bound Moisture

In contrast, bound moisture is chemically or physically held within the material’s structure. This type of moisture is more difficult to remove, requiring higher temperatures and longer residence times to facilitate its release. One example is the water contained within the crystal lattice of gypsum (CaSO₄·2H₂O), which requires calcination to remove.

Comparison Summary:

- Free Moisture: Easily removed with low-to-moderate heat (e.g., water on sand, granules, or pellets). Best removed in a rotary dryer.

- Bound Moisture: Requires high temperatures to break chemical or physical bonds (e.g., gypsum crystal water, hydrated alumina). Typically removed in a kiln.

Why Remove Moisture Before Calcination and Other High-Temp Treatments

In high-temperature processes such as calcination, free moisture is almost always removed first for the following reasons:

Lower energy barrier

Free moisture evaporates at or near the boiling point of water (100°C at atmospheric pressure), requiring less energy to remove than bound moisture, which is held by stronger physical or chemical forces.

Precursor to higher-temperature reactions

Moisture must be removed before decomposition, phase change, or sintering can occur, as it interferes with temperature profiles and reaction kinetics.

A typical thermal process follows this sequence:

- Free moisture evaporates first (~100°C)

- Temperature continues rising to drive off bound moisture (often >200–300°C)

- Thermal reactions proceed (e.g., decomposition, phase change)

Attempting to initiate thermal reactions before moisture removal can result in poor conversion, low product quality, and excessive fuel use.

Understanding Rotary Kilns and Their Intended Function

While rotary kilns can facilitate moisture reduction, they are designed to induce a phase change or chemical reaction within a material and do not offer the same level of efficiency as a rotary dryer. As such, relying on a rotary kiln as the primary moisture removal system introduces several key drawbacks:

Process Efficiency

Moisture absorbs significant amounts of thermal energy during evaporation. If moisture isn’t removed beforehand, much of the heat energy intended for driving chemical reactions will instead be consumed just to vaporize water—reducing process efficiency.

Temperature Uniformity

The presence of moisture can disrupt uniform temperature distribution within the kiln bed. As water evaporates, it cools localized regions, leading to inconsistent reaction zones and incomplete conversion.

Material Integrity

Rapid moisture evaporation inside a hot kiln can cause spalling, cracking, or disintegration of particles, especially in porous materials. This not only compromises product quality but may also create dust or fines that lead to particulates in the off-gases, equipment wear, or system plugging.

Lower Heat Transfer Rate

Rotary kilns are less efficient at removing free moisture than rotary dryers. Kilns typically lack internal flights because the refractory lining cannot withstand repeated mechanical impact. As a result, materials tend to slide rather than shower through the hot gases, limiting heat transfer surface area. Despite their higher operating temperature, kilns transfer heat less effectively, consuming more energy for the same moisture removal.

A FEECO Customer Service Engineer inspects the refractory in this rotary kiln

Capital Costs

The extended residence times and higher temperatures of rotary kilns require them to be constructed from high-temperature alloys and lined with refractory material to protect the shell. This adds significantly to capital costs.

Additionally, to achieve adequate moisture removal without showering action, kiln length would likely need to be extended—further increasing the expense. Adding a rotary dryer as a pre-conditioning step is often more cost-effective.

Refractory Service Life

High-moisture materials increase the risk of thermal shock to the kiln’s refractory lining, leading to premature wear or failure. A low-moisture, consistent feed helps preserve refractory life and maintain stable kiln operation.

When Moisture Reduction in a Rotary Kiln Might Make Sense

While rotary kilns are generally not ideal for drying, there are several cases where using the kiln for limited moisture removal may be acceptable or necessary:

Free Moisture Content is Low

When the material has minimal free moisture, the efficiency trade-off may be acceptable to avoid installing a separate dryer.

Space Constraints Exist

If plant layout cannot accommodate additional equipment, drying within the kiln may be necessary despite the performance drawbacks.

When Moisture is Bound

When a material contains only bound moisture (e.g., crystal water or chemically bonded moisture), a rotary dryer cannot achieve the necessary thermal input—making the kiln essential.

Evaluating Process Design

Determining whether a rotary dryer, rotary kiln, or combination of both is best suited for a given application often requires pilot testing.

The FEECO Innovation Center features both pilot-scale rotary dryers and kilns, allowing customers to simulate real-world drying behavior, reaction performance, and system dynamics. These tests provide the critical data needed to inform equipment sizing, process optimization, and long-term reliability.

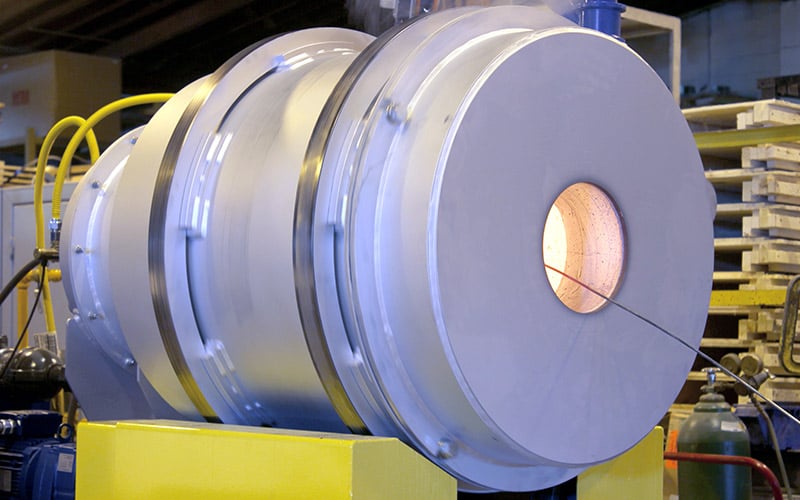

Direct-fired batch kiln used for testing in the Innovation Center

Conclusion

While rotary kilns can achieve moisture reduction, they are typically not the most efficient or cost-effective solution when drying is the primary objective. Instead, rotary dryers offer significant advantages in energy efficiency, process control, and overall performance. However, in some specialized processes—especially when bound moisture is present—moisture removal within a kiln may be appropriate.

FEECO has decades of experience designing custom thermal processing systems, including both rotary kilns and dryers. We work closely with clients to assess material needs, conduct pilot testing, and engineer solutions that strike the right balance between performance, cost, and reliability.

Whether you’re evaluating a new thermal process or troubleshooting an existing one, our team is here to help. To get help with your rotary kiln operation, contact us today!