BULK MATERIAL HANDLING EQUIPMENT & SYSTEMS

FEECO’s engineered bulk material handling equipment and systems are rugged, dependable, and built to last. We can design and supply flexible bulk material handling systems for industries ranging from minerals and ores, to fertilizers and chemicals.

Our custom equipment and systems can assist in every aspect of handling, including loading and unloading bulk solids for transport or storage, sourcing and feeding raw materials, moving finished product around the facility, as well as carrying material throughout the entire production process.

BENEFITS OF A WELL-DESIGNED BULK MATERIAL HANDLING SYSTEM

Bulk material handling equipment can be a facility’s worst adversary or its most valuable asset.

The custom specifications of each unique facility, along with the properties of the material handled, make designing equipment specifically for its intended application essential. Through properly designed equipment, plant managers can often achieve the following benefits:

- Enhanced flowability

- Optimized production line efficiency

- Greater output

- Better process control capabilities

- Reduced labor requirements

- Improved safety

- Decreased housekeeping

- Reduced downtime for troubleshooting and maintenance

- Promotion of equipment longevity

OUR BULK SOLIDS HANDLING EQUIPMENT LINE INCLUDES:

Ancillary Equipment for Bulk Material Handling Systems:

FEECO’s expertise in providing a wide range of additional bulk material handling equipment to complement its base product line means a custom-designed system can be supplied to meet the specific needs of the project based on material characteristics and site specifications.

We routinely integrate equipment such as traveling trippers, reclaim units, weighing devices, crushing / sizing machinery, transfer / screening towers, hoppers, chutes, feeders, and more into our scope of design and supply in material handling.

FEECO is capable of meeting the requirements necessary for CE marking equipment.

All FEECO equipment and process systems can be outfitted with the latest in automation controls from Rockwell Automation. The unique combination of proprietary Rockwell Automation controls and software, combined with our extensive experience in process design and enhancements with hundreds of materials provides an unparalleled experience for customers seeking innovative process solutions and equipment. Learn more >>

APPLICATIONS

FEECO provides custom, heavy-duty bulk material handling equipment and systems for a variety of applications. Materials we commonly provide handling systems for include:

- Aggregates

- Aluminum

- Chemicals

- Clay

- Coal & Coke Products

- Copper Concentrates

- Dewatered Scrubber Sludge

- Fertilizers & Soil Amendments

- Fly Ash

- Glass

- Gypsum & Synthetic Gypsum

- Iron Ore & Taconite Pellets

- Lime/Cement Kiln Dust

- Limestone

- Manure

- Minerals and Ores

- Paper Pulp and Sludge

- Phosphates

- Potash

- Roofing Granules & Abrasives

- Sand

- Wood Chips

CRITICAL ASPECTS OF DESIGNING BULK MATERIAL HANDLING EQUIPMENT

Designing a seamless bulk material handling system relies on several factors, which can be broken down into two categories: material characteristics and site/design specifications:

MATERIAL CHARACTERISTICS THAT INFLUENCE DESIGN:

- Bulk density

- Angle of repose

- Moisture content

- Particle size distribution (PSD)

- Material temperature

- Material fragility

- Special requirements such as toxicity, potential for combustion, abrasivity or corrosiveness, and more

SITE/DESIGN SPECIFICATIONS THAT INFLUENCE DESIGN:

- Intended capacity

- Spatial constraints

- Necessary equipment height and length (conveyor rise and run)

- Environmental factors such as ambient temperature, whether the equipment will be operated indoors or outdoors, proximity to coast, and more

- Requirements for accessories such as walkways, service platforms, belt skirts, and more

BENEFITS OF FEECO BULK MATERIAL HANDLING EQUIPMENT & SYSTEMS

Industry Expertise: FEECO has been providing custom equipment and handling systems since 1951 for the wide range of industries with challenging handling requirements.

Heavy-duty Design and Fabrication: All FEECO equipment is designed to the highest quality standard for rugged handling in demanding conditions. Our equipment has a well-earned reputation for longevity.

Customized Solutions: FEECO engineers each piece of equipment and complete handling system around the specific requirements and characteristics of the material to be handled.

Parts & Service Support: The FEECO Customer Service Team offers all the services necessary to keep bulk handling equipment running its best. This includes inspections and audits, troubleshooting assistance, routine maintenance and repairs, retrofits, and spare parts.

RESOURCES

BULK MATERIAL HANDLING ARTICLES

Agricultural vs. Industrial Bucket Elevators: Why the Right Choice Matters

Confusion often arises when sourcing a bucket elevator, with prices varying widely from one supplier to the next. The reason? The …

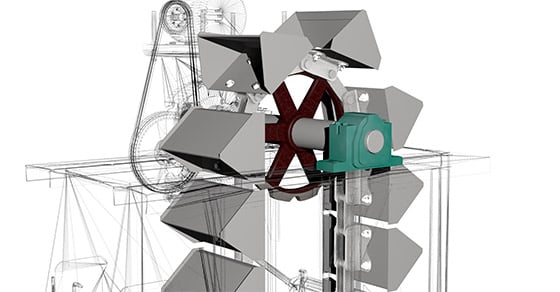

Bucket Elevator Design: Centrifugal Vs. Continuous

The choice between continuous and centrifugal bucket elevators is the starting point for bucket elevator design, with implications on each decision …