Biosolids granulation is the transformation of biosolids into a granular product that is nearly odor-free and rich in nutrients.

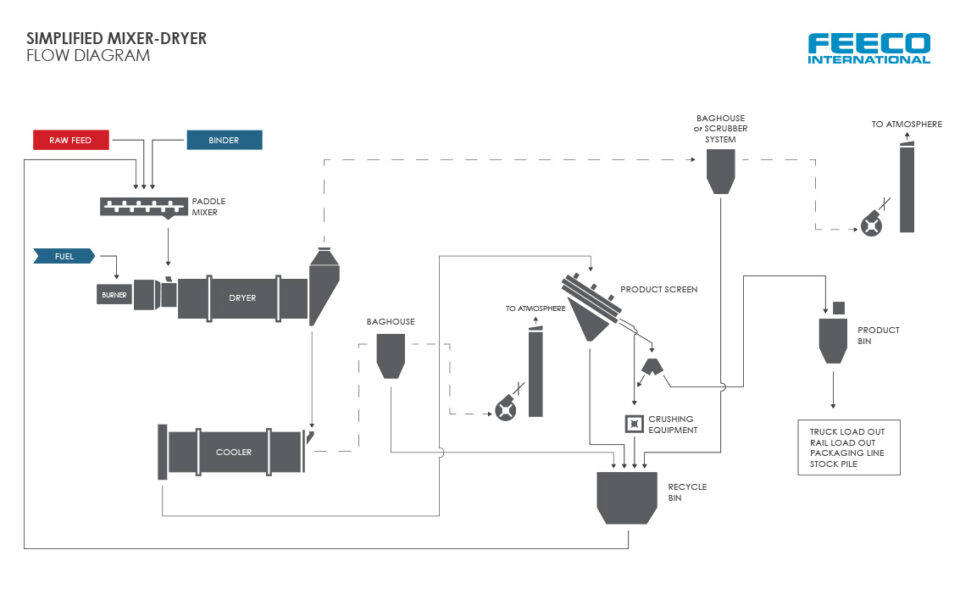

The diagram below highlights a mixer to dryer granulation setup.

Part one of the process takes place in a mixer, generally in a pugmill mixer or paddle mixer. Here, raw feed and binder are thoroughly mixed, and granulation occurs.

Next, the granules produced in the pugmill mixer are fed to a rotary dryer. The tumbling action of the dryer polishes and rounds the granules into their final form.

After the dryer, the granules are fed to a rotary cooler where the product is cooled. The product is then screened, and both undersize and oversize granules are crushed and fed back to the beginning of the process as recycle.

While biosolids present challenges to municipalities in their current form, granulation offers enhanced value, as well as economic and environmental benefits.

To learn more about FEECO’s granulation systems, visit our biosolids processing webpage, or contact a FEECO expert today!