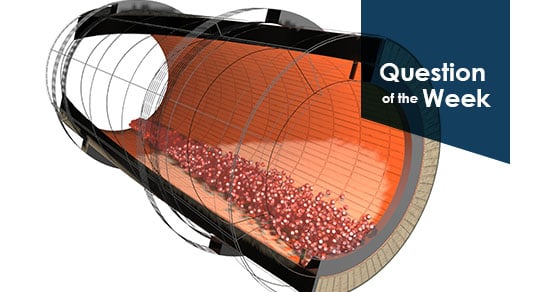

Dams are used to increase the retention time or bed depth in a rotary kiln. Material builds up behind the dam, forcing retention time and bed depth to increase. Material then spills over the dam and discharges from the rotary kiln.

Since most rotary kilns use a counter current air flow, end dams are commonly used. End dams efficiently hold the material where the air is warmest (at the discharge end in a counter current kiln). Internal dams can also be used if a discharge end dam is not sufficient.

FEECO is a leading manufacturer of highly engineered rotary kilns, all custom designed to suit the needs of the material and process at hand. To learn more, download our e-book, or contact us today!