The FEECO Innovation Center is a state-of-the-art testing facility where we can test both agglomeration and thermal processes at batch and pilot scale to assist in your R&D efforts.

Testing in the FEECO Innovation Center allows you to gather valuable material and process data. Whether you’re looking to develop a new product, solve a material problem, develop a new process, or optimize an existing one, our process experts can work with you to develop a customized testing program around the answers you need. We can also generate small samples of product for field trials and further testing.

We use the data gathered during testing to scale up the process and manufacture custom equipment, tailored to your exact processing needs.

Bulk Solids Process Development & Optimization for the Fertilizer, Mining, and Chemical Industries

Equipped with unmatched expertise and an extensive array of process equipment, the FEECO Innovation Center is an essential resource for producers looking to develop a process to dry, thermally treat, mix, condition, or agglomerate/granulate their bulk solids. Coating of granular products can also be tested.

The Innovation Center serves nearly every industry, handling a wide range of materials. We regularly test:

- Adsorbents

- Animal feed products

- Carbon products

- Catalysts

- E-waste and metal recovery applications

- Fertilizers (NPK, Potash, MAP, DAP, Phosphates, etc.)

- Industrial by-products (EAF Dust, Cement Kiln Dust, Fly Ash, Syn Gyp, etc.)

- Manures and animal bedding

- Metallic ores and compounds

- Pulp and paper residuals (paper sludge, etc.)

- Soil amendments (Limestone, Gypsum, Compost, Recovered wastes and by-products, etc.)

Process Development Stages

Depending on the testing objective(s) and what is already known about the material, testing is typically conducted in the following stages:

Confirm Feasibility (Proof of Concept)

The Innovation Center can confirm feasibility and establish proof of concept of an intended process through batch-scale testing. This type of testing typically consists of an initial, non-witnessed test that explores the possibility of creating a product from a representative sample of the source material. From this, producers can gain an understanding of whether or not the intended process merits further exploration on a larger scale.

Proof of Product

Proof of product testing consists of a more in-depth batch test in which more time is spent determining whether the source material can be made into a product that meets the desired specifications.

This may include exploration of various binding agents, equipment configurations, pretreatment requirements, as well as other process and equipment variables that influence end product specifications.

Proof of Process

Proof of process testing consists of continuous testing in our pilot plant. This pilot-scale testing aims to establish the viability of the intended process on a continuous basis, as well as the equipment setup and parameters required.

Process/Product Optimization

Once proof of process has been established, testing moves on to process and product optimization. This stage consists of in-depth testing in our pilot plant, with tests designed to optimize product quality and process efficiency for commercial-scale production.

PROCESS EQUIPMENT AVAILABLE FOR TESTING

From testing on a single piece of equipment, to a continuous process loop, we offer a variety of equipment types, as well as support equipment to cover the full range of process testing needs. In addition, we are capable of making on-site, large-scale modifications to our facility in order to accommodate your bulk solids testing needs.

Batch- & Pilot-Scale Testing Equipment:

The following equipment is available for testing. For those interested in testing at their own on-site R&D facility, we also offer a range of rental equipment.

AGGLOMERATION: BATCH EQUIPMENT

- Disc Pelletizer

- Pin Mixers (2)

AGGLOMERATION: CONTINUOUS EQUIPMENT

- Disc Pelletizers (2)

- Rotary Granulator

- Paddle Mixer/Pug Mill

- Pin Mixer

- Hammer Mill

- Rod Mill

- Prater Mill

- Rotex Screen – 2 deck

- Circular Screen

- Coating Drum

- Curing Drum

THERMAL: BATCH EQUIPMENT

- Rotary Kiln

- Indirect Kiln

- Flight Simulator

THERMAL: CONTINUOUS EQUIPMENT

- Rotary Kiln

- Indirect Kiln

- Rotary Dryer

- Fluid Bed Dryer

MATERIAL HANDLING (ALL CONTINUOUS)

- Belt Conveyor

- Bucket Elevator

- Steep Incline Conveyor

- Various Feeders

SUPPORT: BATCH EQUIPMENT

- Muffle Furnace

- Fluid Bed Sample Dryer

- Tray Oven

SUPPORT: CONTINUOUS EQUIPMENT

- Steam Generator with Steam Tanks

BENEFITS TO FEECO r&d TESTING

The FEECO Innovation Center provides a valuable opportunity to test your material or process in a controlled environment. Some of the many advantages to testing with FEECO include:

Material Testing Experience:

FEECO has been a pioneer in material processing since the 1950s, with in-depth knowledge around thousands of materials. Because of this, we are often able to expedite the testing process, with an understanding of what typically works and what doesn’t.

Complete Process Knowledge:

As experts in process design, FEECO can offer expertise not only in each step in the process, but also in how the process comes together as a whole. This allows us to better understand your project on both a micro and macro level.

Process Scale-up Capabilities:

Once the process configuration has been defined, FEECO can aid in process scale-up, as well as manufacturing the custom equipment needed to build the commercial-scale plant.

WASTE RECOVERY & REUSE EXPERTISE

The FEECO Innovation Center has helped companies around the world to transform various wastes and process by-products into value-added products through agglomeration and thermal processing methods. The list below looks at some of the material and waste transformations performed in recent years, as well as the processing methods used to transform each material.

| Beginning Material | Final End Product | Agglomeration | Drying | Blending | Thermal | Roll Compaction |

| Sulphur Stack Emissions | Granulated Fertilizers | x | x | x | ||

| Calcium Sulfate | Fertilizer Pellets | x | x | x | ||

| Ash (Wood, Fly) | Fertilizer Pellets | x | x | |||

| Bentonite Clay | Cat Litter Granules | x | x | x | ||

| Calcium Chloride | Ice Melt Pellets | x | x | |||

| Calcium Carbonate | Fertilizer Pellets | x | x | |||

| Carbon Black Dust | De-dusted Pellets | x | x | |||

| Cement Kiln Dust | Calcium Fertilizer Pellets | x | x | |||

| Cell Phone Batteries | Lithium, Zinc Metal Recovery | x | ||||

| Clay | Cat Litter, Oil Dry Granules, Encapsulate Seeds | x | x | x | ||

| Coal Dust | De-dusted Coal Pellets | x | x | x | ||

| Composts (Yard Waste) | Fertilizer Pellets | x | x | x | ||

| Copper Dust | Metal Recovery Pellets | x | x | x | ||

| Corn Cobs | Cat Litter, Oil Dry Pellets | x | x | x | ||

| Clay | Proppants | x | ||||

| Dredge Sludges | Non-leaching Granules | x | x | x | ||

| Electric Arc Furnace (EAF) Dusts | Metal Recovery | x | x | x | ||

| Ethanol Plant Waste (DDG) | Animal Feed | x | x | x | ||

| Foundry Dust | Metal Recovery | x | x | x | ||

| Gold Ore Dust | Precious Metal Recovery | x | x | x | ||

| Grain Dust | Non-explosive Pellets | x | x | x | ||

| Gypsum Wallboard Waste | Fertilizer, Cat Litter Pellets | x | x | x | ||

| Humate | Fertilizer Pellets | x | x | x | ||

| Iron Oxide | Metal Recovery Pellets | x | x | x | ||

| Lime (Waste Water Treatment Sludge) | Calcium Fertilizer Pellets | x | x | x | ||

| Limestone | Calcium Fertilizer Pellets | x | x | x | ||

| Talc Ore | Sterilized Baby Powder | x | ||||

| Manure – Cattle/Chicken/Hog | Fertilizer Pellets | x | x | x | ||

| Soda Bottles | Recycled Plastic | x | ||||

| MAP Fertilizers | Fertilizer Pellets | x | x | x | ||

| Municipal Wastes | Fertilizer, Fuel Pellets | x | x | x | ||

| Nitrogen Fertilizers | Fertilizer Pellets | x | x | x | ||

| NPK Blends | Fertilizer Pellets | x | x | x | x | |

| Paper Sludge | Fertilizer, Cat Litter | x | x | x | ||

| Petroleum Coke Dust | Fuel Pellets | x | x | x | x | |

| Phosphates Powder | Fertilizer Pellets | x | x | x | ||

| Potassium Chloride | Fertilizer Pellets | x | x | x | x | |

| Saw Dust | Cat Litter, Fuel Pellets | x | x | x | x | |

| Soy Flour | Animal Feed | x | x | x | ||

| Steel Dusts and Sludges | Metal Recovery Pellets | x | x | x | x | |

| Sugar | Sugar Pellets | x | x | x | ||

| Sulphur Dust | Non-explosive Pellets | x | x | x | ||

| Tar Sands Waste Sludge | Substitute Fuel Pellets | x | x | x | ||

| Titanium Metal Shavings | Metal Recovery | x | x | x | ||

| Iron Ore | Metal Recovery Pellets | x | x | |||

| Glass Batch | Glass Blend | x | x | x | ||

| Ceramic / Aluminum | Refractory | x | x | |||

| Paper Sludge | Bright White Clay | x | ||||

| Gypsum | Fertilizer Pellets | x | x | |||

| Zinc Oxide | Metal Recovery Pellets | x | x | x | ||

| Nickel Ore | Metal Recovery Pellets | x | x | |||

| Kaolin Clay | Coating Paper | x | x | |||

| Tungsten Oxide | Metal Recovery Pellets | x | x | x | ||

| Raw Coal | Purified Coal | x | ||||

| Bone Meal | Fertilizer | x | x | |||

| Ammonium Sulfate | Fertilizer | x | ||||

| Diatomaceous Earth | Filter Agent | x | x | |||

| Titanium Dioxide | Pigment Pellets | x | x | x | ||

| Urea Fertilizers | Coated to prevent moisture absorption | x | x | x |

PROCESS DATA COLLECTION

FEECO is a Rockwell Automation Partner, providing integrated process control solutions, both as a service in the Innovation Center and as part of a system purchase.

During testing, we can monitor, trend, and adjust various data points in real-time, all from a single interface or mobile device, giving you an aerial view of your process and equipment performance. Depending on the type of testing being conducted, tracked data might include:

- Current (Amps)

- Feed Rate

- Flow Rates/Product Flow

- Fuel Usage

- Horsepower

- System Pressure

- Temperature

- Torque

- Gas Sampling & Analysis (Oxygen, Carbon Monoxide, Nitric Oxide, Nitrogen Dioxide, Sulfur Dioxide, and combustibles discharged from various thermal

These capabilities provide unmatched data collection and reporting capabilities.

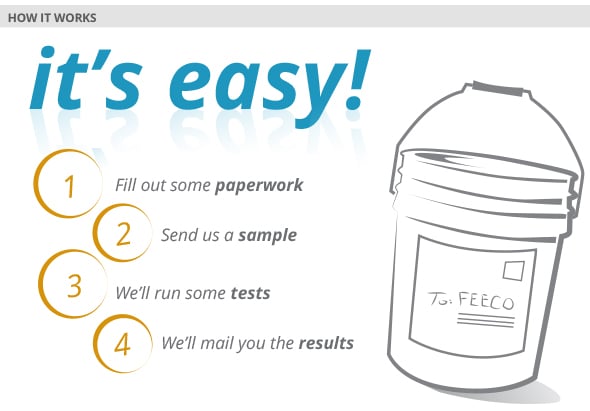

Ready to Test Your Process?

Contact us today to discuss your batch- or pilot-scale testing needs!

RESOURCES

TESTING PROFILES

MATERIAL TESTING & TRANSFORMATION ARTICLES

Challenges in Potash Processing

More than 30 million tonnes of potash are produced worldwide each year, making it an important mineral for a number of …

Challenges in Limestone Processing

Limestone processing equipment plays a critical role in transforming quarried limestone into a variety of valuable products, but the material’s diverse …