The frac sand dryer has become a critical component in meeting today’s growing demand for high-quality proppants used in hydraulic fracturing. As rig counts rebound and the volume of sand used per well continues to climb, the global frac sand market reached a valuation of USD 8.1 in 2024 and is expected to reach USD 16.1 billion by 2033 – a CAGR of 7.06%.[1]

In step with this growth, the drying systems used to process frac sand have evolved significantly, driven by the industry’s increasing focus on eliminating inefficiencies and improving product quality.

No longer viewed as just a basic processing step, the drying phase—and the equipment behind it—has become a key differentiator in operational performance and cost-efficiency.

Frac Sand Market Overview

The resurgence in frac sand demand is being fueled by several converging trends in the oil and gas industry. As producers focus on maximizing well productivity, the volume of sand used per well has reached record highs. Horizontal drilling and multi-stage hydraulic fracturing techniques now routinely require thousands of tons of sand per well to maintain fracture openings and optimize hydrocarbon flow.

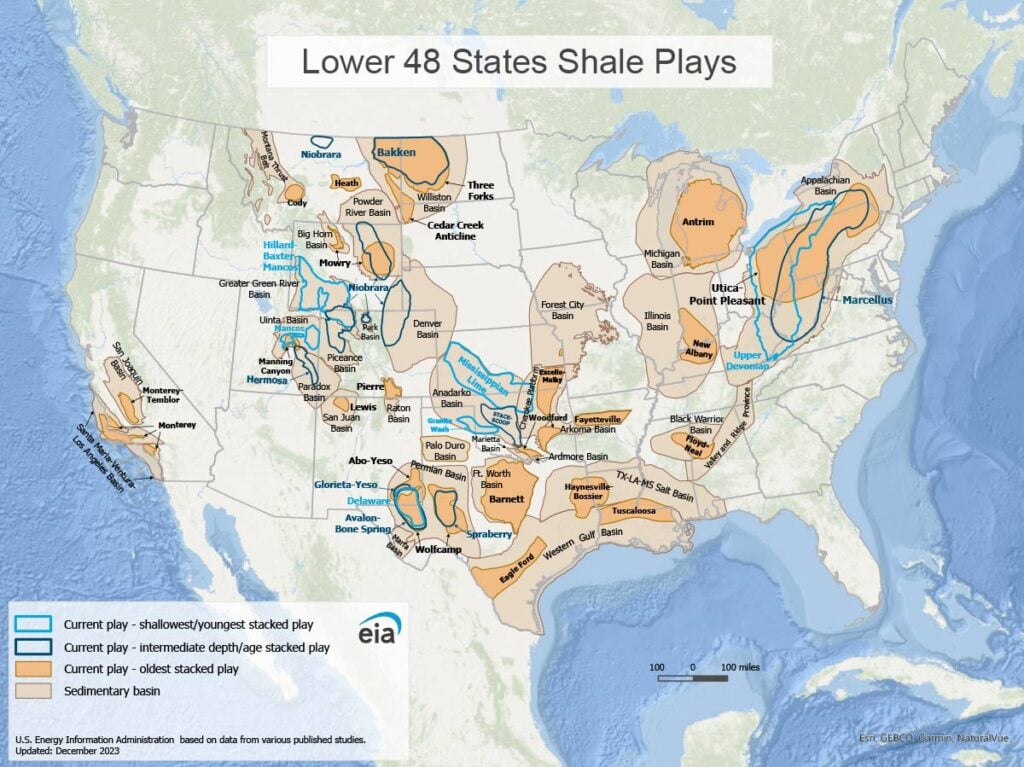

In addition, the United States remains one of the world’s leading producers of oil and gas, with major basins such as the Permian, Marcellus, and Eagle Ford driving proppant consumption. Even amid global efforts to diversify energy portfolios, oil and gas remain essential to meeting current energy needs, keeping pressure on domestic sand supply chains.

Lower 48 States Shale Plays – Source: Energy Information Administration[2]

The growth in frac sand demand is also being supported by favorable drilling economics, rising energy consumption, and continued investment in shale development across North America.[1]

These conditions have intensified the need for robust, high-throughput processing infrastructure—particularly when it comes to the drying stage.

The Critical Role of Frac Sand Dryers

Frac sand is washed after extraction to remove clay and other impurities, but this process leaves residual moisture in the material. Drying is an essential step before the sand can be used in hydraulic fracturing, as moisture affects both flowability and performance as a proppant.

After washing and partial air drying via stockpiling, the sand is conveyed into a dedicated drying plant. Here, the dryer removes remaining moisture and the material is screened into precise size fractions to meet market specifications. Material handling equipment such as conveyors and bucket elevators transport the sand throughout the process.

In addition to improving sand quality, drying significantly reduces transportation costs by lowering the sand’s weight, which is especially important given the long hauls to many well sites.

Types of Frac Sand Dryers

Two primary types of industrial drying systems are used in frac sand processing:

- Rotary Dryers

- Fluid Bed Dryers

While both systems can offer an effective drying solution, rotary dryers have gained favor from frac sand producers, for their high throughput capacity, tolerance to variable feedstocks, and mechanical simplicity.

In contrast, fluid bed dryers require a highly uniform feed and are more sensitive to fluctuations in particle size and moisture content—common characteristics of raw frac sand.

How Frac Sand Dryer Design is Evolving

The overall concept of drying in the frac sand industry has changed as well; what was once an industry that favored low costs over design and durability, the frac sand industry has evolved to meet the changing needs of the market.

As producers increasingly prioritize operational efficiency, dryer design has become more sophisticated. Advanced frac sand dryers boast a number of upgrades when engineered around the unique characteristics of frac sand:

1. Focus on Energy Efficiency and Throughput

In response to rising energy costs and pressure to reduce environmental impacts, frac sand producers are placing greater emphasis on minimizing fuel consumption per ton of dried material. This has led to improvements in burner selection, combustion tuning, heat transfer efficiency, and control systems.

At the same time, dryers must be engineered to accommodate feed rates exceeding 200 tons per hour to support the intense production demands of shale plays in the Permian Basin, Marcellus, and beyond.

Optimizing these factors—energy efficiency, thermal performance, and system control—must be done in conjunction with the unique challenges of drying abrasive, fine, and variable frac sand, making high-capacity drying both a technical and operational balancing act.

Proper seals at the inlet and discharge breechings are also essential in reducing energy losses by preventing air ingress, which would lower the dryer’s internal temperature, causing a drop in efficiency and potentially under-drying product.

2. Minimized Carryover and Dust Emissions

Frac sand’s fine particle size is prone to entrainment in the exhaust gas stream, leading to product loss and emissions challenges. To mitigate this risk while keeping capital costs down and maintaining a high throughput, FEECO recommends using a smaller-diameter drum with increased air flow, in combination with an oversize discharge hood (also referred to as a knockout chamber) that allows fines to settle instead of being carried away.

These changes help to support compliance with crystalline silica dust regulations set out by OSHA and MSHA.

Here again, proper sealing ensures the system can perform as designed.

Knockout chamber/discharge breeching on a FEECO frac sand dryer

3. Sustained Product Integrity

Drillers require frac sand to meet various quality criteria for performance as a proppant, based on standards set forth by the American Petroleum Institute (API) and the International Organization for Standards (ISO). These qualities can be summarized as:[3]

- High silica content

- Homogeneous grain size

- High sphericity and roundness

- High crush resistance

- Low solubility

- Low turbidity

Frac Sand Quality: Crush Resistance

Of particular importance is crush resistance; as a proppant is expected to hold open rock fissures, particles with a low crush resistance risk breaking down and clogging well fissures, inhibiting hydrocarbon flow. Overheating during drying can reduce the product’s crush strength, making careful control over the drying process essential to meeting market expectations.

Similarly, overheating of the sand can also increase dust generation, which has impacts on product quality and performance, as well as drying emissions.

One way in which producers can ensure product quality is not compromised during the drying process is through preventing contact between the product and burner flame, which could otherwise degrade frac sand and compromise its crush resistance.

Preventing Flame Contact With A Combustion Chamber

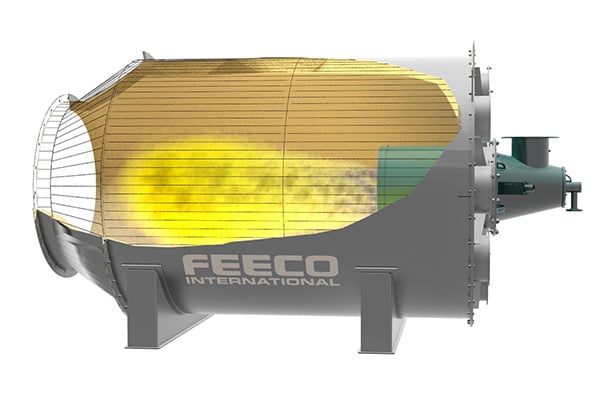

By incorporating a refractory-lined combustion chamber into the dryer, producers can protect frac sand from flame exposure, while achieving even, efficient heat transfer down the length of the drum.

3D model of a FEECO combustion chamber showing burner flame containment

FEECO Frac sand dryer with combustion chamber (burner also shown)

The incorporation of a combustion chamber not only protects product integrity but also contributes to consistent drying across varied sand particle sizes.

4. Engineered for Abrasive Service

The quartz-rich composition of frac sand makes it highly abrasive. To handle this, modern dryers should be constructed with quality materials to extend service life and minimize maintenance and downtime. This includes:

- Abrasion-resistant alloys and liners

- Easily replaceable wear components, such as bolt-in flights

- Heavy-duty seals and bearings

Careful selection of construction materials and mechanical components ultimately helps extend equipment life, reduce downtime, and ensure consistent operation in high-throughput settings.

Leaf seal

5. Custom Flighting for Optimal Heat Transfer

Flights—internal lifting mechanisms within rotary dryers—have become increasingly customized for frac sand applications. Common configurations incorporate:

- Advancing flights near the feed end to rapidly move wet material away from the inlet and into the heat zone

- Lifting flights to maximize material-air contact and ensure uniform drying by cascading material through the air stream in an optimized “curtain” across the drum’s interior diameter

Advancing flights (front) help to move sand into the dryer’s heating zone, while lifting flights (behind advancing flights) shower material through the drum’s cross section for optimal heat transfer.

Conclusion

As the frac sand industry continues to scale in response to increased drilling activity and growing proppant demand, dryer technology has evolved in tandem. The transition from basic commodity dryers to purpose-built, high-efficiency systems reflects the sector’s broader focus on eliminating inefficiencies, reducing operating costs, and improving product quality. In this competitive landscape, dryer systems are no longer just a utility—they’re a strategic asset in maximizing throughput and delivering a premium product to market.

FEECO is a preferred supplier to the frac sand industry, offering custom rotary dryers designed specifically around the material characteristics of the sand being processed. All FEECO dryers are engineered to withstand the abrasive nature of the material while delivering consistent, high-volume output. Just as critical as the equipment itself, our customers rely on us for comprehensive parts and service support—an essential component in keeping operations running smoothly in such a high-demand environment. For more information on our frac sand dryers or services, contact us today!

SOURCES:

- U.S. Geological Survey. (2015). Frac Sand in the United States—A Geological and Industry Overview (Open-File Report 2015–1107). https://pubs.usgs.gov/of/2015/1107/pdf/ofr20151107.pdf

- IMARC Group. (2024, March). Frac Sand Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024–2032. https://www.imarcgroup.com/frac-sand-market-statistics

- U.S. Energy Information Administration. (2023). Shale Gas Production. https://www.eia.gov/oil_gas/rpd/shale_gas.pdf