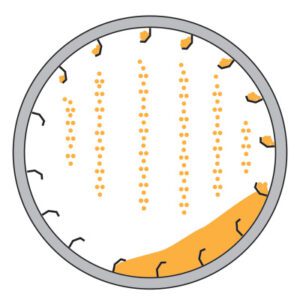

Photo of the Week: Dried Bagasse

This week’s photo shows bagasse after processing in the FEECO Lab. Bagasse is the fibrous material left over from the sugarcane extraction process. This material is sometimes used as a source of biofuel production, but must be dried prior to use. Drying can be carried …