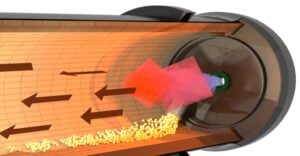

Co-Current Vs. Counter Current: Kiln Air Flow

Many factors are taken into consideration when designing a rotary kiln. Each affects the ability to produce a desired chemical reaction/phase change in an efficient manner. Characteristics such as bulk density, specific heat, and flowability, among others, all interact to influence how the material will …