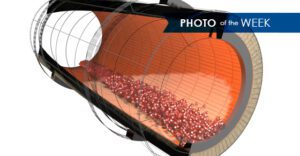

Photo of the Week: 3D Rotary Kiln Dam

This week’s photo highlights a rotary kiln dam in 3D. Oftentimes, it is necessary to increase retention time and/or bed depth in a kiln. This is achieved through the use of a dam. A rotary kiln dam works by forcing material to build up behind …