Rotary Drum Agglomerator vs Granulator – What’s the Difference?

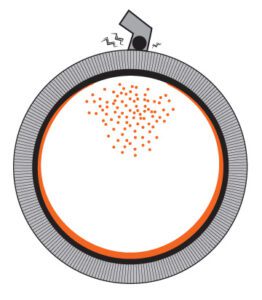

When looking for versatile manufacturing equipment capable of producing granules, rotary drums are often the equipment of choice. However, confusion frequently arises in choosing between an agglomerator and granulator. Because rotary drums are flexible in design and capable of processing large capacities, they are extensively …