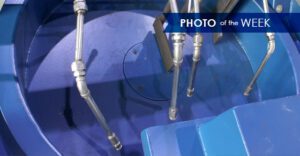

Photo of the Week: 24” Pin Mixer

Pin mixers are used for various agglomeration processes including material conditioning, mixing, de-dusting, agglomerating, and micro-pelletizing. They can be used as a stand-alone agglomeration unit, or in combination with a disc pelletizer or agglomeration drum, to produce a pelletized product. Pin mixers use a rotor …